Winches and pulleys are mechanical devices widely used for lifting, moving, and positioning loads. While both serve similar purposes, they operate on different principles and offer distinct advantages.

Understanding the differences between winches and pulleys is crucial for selecting the right tool for your specific needs, ensuring safe and efficient operations.

In this comprehensive guide, we’ll explore the mechanisms, advantages, applications, and common misconceptions.

What is a Winch?

A winch is a mechanical device equipped with a drum, around which a rope or cable is wound. By turning the drum, you pull the cable and, consequently, the load towards the winch. Winches can be powered manually or by electric, hydraulic, or pneumatic power.

They’re ideal for pulling objects over relatively short distances, vertically or horizontally, and are commonly seen on off-road vehicles and boats.

What is a Pulley?

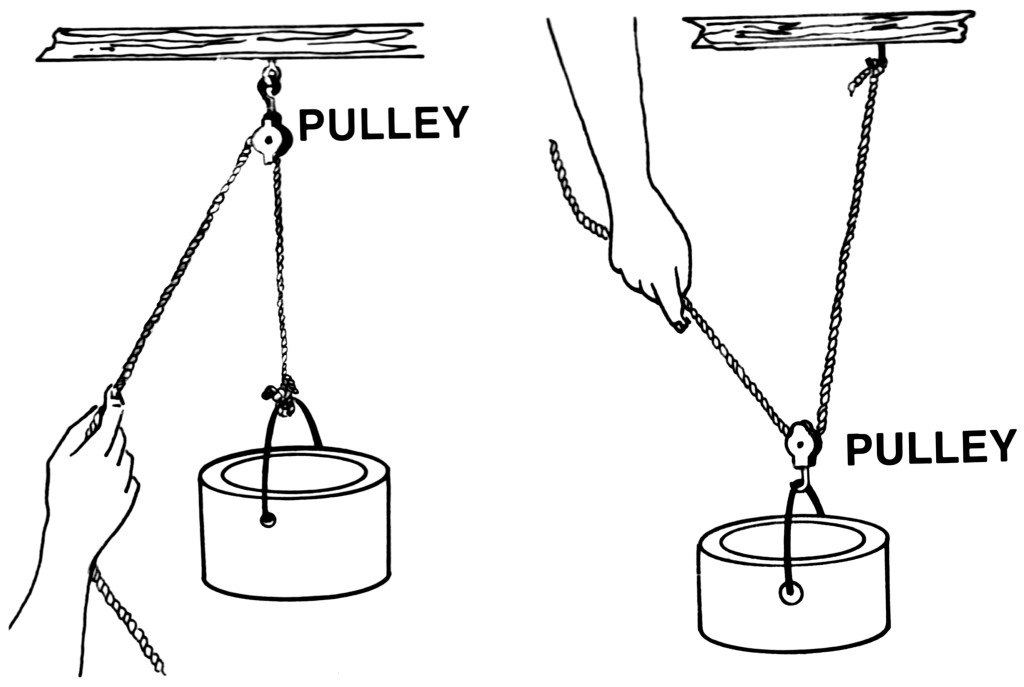

A pulley consists of a wheel on an axle or shaft, designed to support movement and change of direction of a taut cable or belt.

Pulleys can be simple, with a single wheel, or compound, with multiple wheels, allowing for a distribution of force and enabling you to lift loads with less effort.

Pulleys are the essence of clever engineering, used to lift heavy loads vertically. They shine in applications like construction cranes, theater curtains, and even in your gym’s weight-lifting equipment.

The magic of pulleys is in their ability to make lifting tasks feel lighter, thanks to the mechanical advantage they offer.

Key Differences Between Winch and Pulley

At first glance, both mechanisms might seem to serve the same purpose: moving heavy loads.

However, the manner in which they accomplish this, and the applications they are best suited for, vary significantly.

Let’s delve deeper into these differences to provide a clearer picture.

Winches: The Powerhouses for Pulling

Winches are all about brute force and direct pulling power. They consist of a drum or spool, around which a rope or cable is wound.

When the drum is turned, either manually or by a motor (electric, hydraulic, or pneumatic), it winds the cable, pulling whatever is attached to the other end towards the winch.

This makes winches especially valuable in scenarios where you need to drag or tow heavy objects across a horizontal plane or up an incline.

The power source behind a winch can vary, allowing them to be incredibly versatile.

Electric winches are common for light to medium tasks, such as vehicle recovery or small-scale construction projects, because they can be easily powered by a vehicle’s battery or another portable power source.

Hydraulic winches, offering more strength, are often found in marine and industrial settings, where they can be integrated into a system’s existing hydraulic power source.

Manual winches, though requiring more physical effort, are invaluable in remote locations where power sources might not be readily available.

Pulleys: Masters of Elevation

Pulleys, on the other hand, excel in vertical lifting. A pulley system uses one or more wheels over which a rope or cable is looped.

This setup can significantly reduce the effort needed to lift a heavy load upwards. The beauty of pulley systems lies in their mechanical advantage, which can be increased by adding more pulleys into the system, known as a compound pulley system.

This is why pulleys are often used in construction (to lift materials to higher floors), in theaters (to raise and lower scenery and curtains), and in various lifting equipment within the fitness and industrial sectors.

The mechanism of a pulley allows for a distribution of force. When multiple wheels are involved, each rotation distributes the load across the system, making it easier to lift heavy items with less force.

This mechanical advantage is calculated based on the number of rope segments supporting the load, allowing precise control over the lifting process, which is crucial in many engineering and construction applications.

Choosing Between Winch and Pulley

The decision to use a winch or a pulley boils down to two main factors: the direction in which the load needs to be moved and the nature of the task at hand.

- For Horizontal Pulling or Dragging: If you’re pulling a boat onto a trailer, dragging a fallen tree, or recovering a stuck vehicle, a winch is your best bet. Its design and operation are optimized for these tasks, providing the power and control needed to pull heavy items towards a fixed point.

- For Vertical Lifting: When the job involves lifting a heavy object straight up—such as hoisting building materials, lifting an engine out of a car, or even raising the sail on a boat—a pulley system is more appropriate. Its ability to lighten the load through mechanical advantage makes lifting more manageable and safer.

Choosing the Right System for Your Needs

It’s not just about whether you need to move something heavy; it’s about understanding the nuances of your project or task at hand.

Let’s break down these factors to help you make an informed decision.

Understanding the Load

The very first thing to consider is the weight of the load you intend to move. Both winches and pulleys can handle heavy loads, but the efficiency and safety of doing so depend on the specifics of the equipment you choose.

For example, winches are available in a range of capacities, from small, manual models for light loads to heavy-duty electric or hydraulic winches designed for pulling several tons.

Similarly, pulleys can be designed to handle different weights by adjusting the number of wheels (sheaves) and the strength of the rope or cable used.

Direction of Movement

The direction in which you need to move the load is a critical factor in deciding between a winch and a pulley.

- Vertical Movement: If your task involves lifting objects upwards—say, hoisting construction materials to a higher floor or lifting a chandelier to be mounted on a ceiling—a pulley system is designed for this very purpose. The configuration of pulleys can provide a mechanical advantage, making it easier to lift heavy items by distributing the force required across multiple points.

- Horizontal or Inclined Movement: For tasks requiring you to pull objects horizontally or along an incline—such as towing a vehicle, dragging logs, or pulling a boat onto a trailer—a winch is more suitable. Winches provide the raw pulling power needed to move heavy items across surfaces, regardless of slight inclines or rough terrain.

Power Sources and Space Constraints

Consider the available power sources and the amount of space you have for the equipment.

- Winches can be manual, but they’re often powered by electricity, hydraulics, or pneumatics. Electric winches, for instance, require access to a power supply (like a vehicle battery or an electrical outlet), while hydraulic winches need a hydraulic system to operate. This means you need to have the appropriate power source nearby or be able to install one.

- Pulleys generally require manual operation or can be part of a more complex system like an electric hoist. The space needed for a pulley system can vary greatly depending on the complexity of the setup. A simple fixed pulley for lifting a plant pot requires minimal space, whereas a compound pulley system to lift heavy construction materials might need a more significant setup area.

Installation Complexities and Control

The complexity of installing either system and the level of control required during the operation are also important considerations.

- Winches might need mounting on a stable surface or vehicle, and understanding how to operate them safely is crucial. They offer direct control over the pulling process but require knowledge of winding and unwinding the cable properly to avoid tangling or damage.

- Pulleys might seem simpler but setting up a system that provides the desired mechanical advantage can be complex. The installation involves not just the pulley itself but also the ropes or cables and potentially multiple pulleys to achieve the necessary lifting power. However, once set up, a pulley system can offer precise control over lifting, allowing for smooth and steady movement of the load.

Practical Examples

- For Construction or Stage Design: If you’re working on a project that requires frequent lifting of materials or scenery vertically, a pulley system can provide the efficiency and control you need, making it possible to lift heavy items safely and with less effort.

- For Vehicle Recovery or Moving Large Objects: If your project involves pulling heavy items over a distance, such as during vehicle recovery operations or when moving large objects on a property, a winch offers the pulling power necessary to accomplish the task effectively.

Common Misconceptions

Let’s debunk some myths and clarify how these mechanisms differ fundamentally, emphasizing that the choice between them depends on the specific requirements of your task, not on a general assumption of superiority.

Misconception 1: Winches and Pulleys Serve the Same Purpose

While it’s true that both winches and pulleys are designed to move heavy loads, they do so in fundamentally different ways and for different purposes.

- Winches are designed to pull loads towards the winch itself, using a drum around which a cable or rope is wound. This action is primarily horizontal but can also include pulling up an incline. The winch converts power (manual, electric, hydraulic, or pneumatic) into pulling force, making it ideal for tasks such as towing vehicles, dragging objects across the ground, or even pulling a sail up a mast in nautical applications.

- Pulleys, on the other hand, are designed to lift loads vertically, making use of a wheel and a rope or belt to create a mechanical advantage. This allows for the lifting of heavy objects with less effort than would be required to lift them directly. Pulleys can be simple, with a single wheel, or compound, with multiple wheels, to increase the mechanical advantage and make lifting even easier.

Misconception 2: One Is Better Than the Other

The notion that one of these mechanisms is inherently better than the other overlooks the importance of context in their application. The best choice depends entirely on the task you need to accomplish:

- If you need to pull a heavy object across a surface or up an incline, a winch is your best option. It’s built for this kind of work, providing the power and durability needed for pulling tasks.

- If your goal is to lift an object vertically, whether it’s construction materials, stage scenery, or weights in a pulley-based exercise machine, a pulley system is designed for this purpose. It offers an efficient way to elevate objects by reducing the amount of force needed.

Misconception 3: They Are Interchangeable

Another common mistake is thinking that winches and pulleys can be used interchangeably. While creative engineering can sometimes adapt these tools beyond their standard applications, such adaptations require careful consideration of the forces involved and often additional safety measures.

The inherent design of each mechanism suits it to its specific tasks, and using them as intended ensures safety, efficiency, and longevity of the equipment.

Also Read: Winch vs Hoist

Conclusion

Both winches and pulleys are invaluable tools in the realm of mechanical lifting and pulling. Understanding their differences and applications is crucial for selecting the right tool for your needs.

Whether you’re involved in construction, automotive recovery, or stage production, knowing when to use a winch or a pulley can make your task easier, safer, and more efficient.

Always prioritize safety, and don’t hesitate to consult with experts to ensure you’re making the best choice for your specific requirements.