A hand winch is a versatile, portable mechanical device that is operated manually to lift, pull, or tension loads.

Hand winches utilize a crank handle, gear mechanism, drum, and brake to convert the rotary motion of the handle into linear cable motion in a controlled manner.

Compared to fixed electric winches, hand winches are lightweight, mobile, and do not require external power sources.

Their simple but robust construction makes them highly adaptable for various lifting, pulling, securing, and anchoring applications across industries and recreational settings.

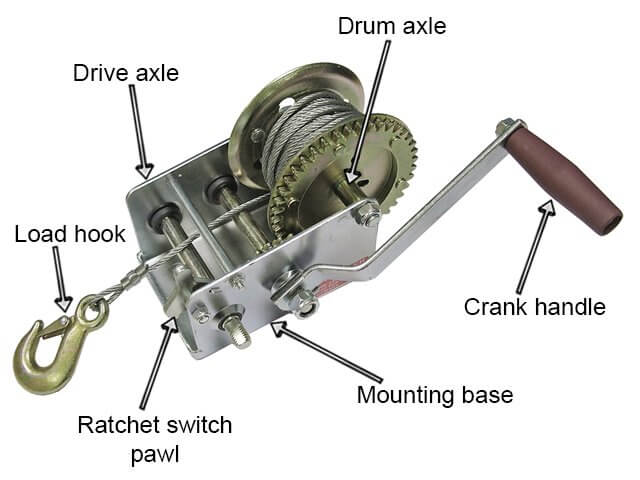

Components of a Hand Winch

Frame

The frame is essentially the backbone of the hand winch. It serves as the structural foundation that holds all the other components together.

Made from durable materials such as steel or aluminum, the frame is designed to withstand the forces exerted during winch operations.

It must be robust enough to support the weight of the load, as well as the mechanical stresses of pulling or lifting.

The design of the frame also allows for secure mounting of the winch to a stable surface or structure, ensuring safety and stability during use.

Drum

At the heart of the hand winch is the drum. This cylindrical component is where the cable or rope is wound around.

As you turn the crank handle, the drum rotates, either winding the cable onto the drum to lift or pull a load, or unwinding it to lower or release the load.

The diameter of the drum affects the mechanical advantage of the winch, with larger drums requiring more force to turn but allowing for longer lengths of cable or rope to be wound.

Gear Mechanism

The gear mechanism is what translates the rotational movement of the crank handle into the winding or unwinding action of the drum.

It consists of a series of gears that reduce the speed of the crank handle’s rotation, increasing the torque (rotational force) applied to the drum.

This means that even a relatively small force applied to the crank handle can move a much larger load.

The gear ratio, which is the ratio of the input speed (crank) to the output speed (drum), is a key factor in determining the winch’s efficiency and load capacity.

Crank Handle

The crank handle is the part of the winch that the operator turns to operate the device.

The length of the crank handle can affect the force required to turn it; longer handles provide more leverage, reducing the amount of force needed to lift or pull a heavy load.

The handle is designed to be user-friendly, often with ergonomic features to make the manual operation as comfortable and as efficient as possible.

Brake

The brake is a safety feature that prevents the drum from rotating in the opposite direction when the crank handle is not being turned.

This is critical for maintaining the position of the load, especially when lifting or holding it in place. The brake ensures that the load doesn’t fall or slide back due to the weight or force acting on it, providing a controlled operation and enhancing safety.

Some hand winches come equipped with automatic brakes that engage as soon as the handle is released, while others may have a manual brake that the operator engages.

Cable or Rope

Finally, the cable or rope is the medium through which the force generated by the winch is applied to the load. Cables are typically made of steel or synthetic fibers, offering high strength and durability.

The choice between cable and rope depends on the application, with cables being preferred for their strength and durability in harsh conditions, and ropes being chosen for their flexibility and ease of handling.

The length and thickness of the cable or rope determine the maximum load capacity and reach of the winch.

How Does a Hand Winch Work?

Understanding how a hand winch operates involves looking closely at the process of converting manual effort into mechanical advantage, enabling the lifting or pulling of heavy loads.

This process hinges on a few key principles and components, each playing a crucial role in the functionality of the winch.

Let’s break down this process step by step for a clearer understanding.

Conversion of Rotary Motion to Linear Motion

The core functionality of a hand winch lies in its ability to transform the rotary motion of the crank handle into the linear motion of the cable or rope.

This is achieved through the winch’s gear mechanism. When you turn the crank handle, this rotational movement is transferred to the gears inside the winch.

Gear Mechanism: Speed Reduction and Torque Multiplication

The gear mechanism is fundamental to the hand winch’s operation. It consists of a series of gears that interact with each other to reduce the speed of the crank handle’s rotation, which in turn increases the torque, or rotational force, applied to the drum where the cable or rope is wound.

This process is essential because it allows a relatively small amount of force applied by the human hand to move a much heavier load.

The gear ratio, which is the difference in size between the crank gear and the drum gear, determines how much the speed is reduced and the torque is multiplied.

A higher gear ratio means that the crank needs to be turned more times to wind the cable a certain length, but it also means that less force is needed to lift or pull a heavy load.

Braking Mechanism: Controlled Operation

The braking mechanism is what allows the hand winch to maintain control over the load, especially when stopping or holding a load in a stationary position.

Without a brake, the load could potentially unwind uncontrollably due to gravity or its weight, leading to accidents or damage.

The brake engages either automatically when the crank is not being turned, or manually by the operator, to prevent the drum from spinning in the opposite direction, thus ensuring the load remains secure.

Operator Input: Adjusting Crank Effort

The operator plays a key role in the winch’s operation. The effort required to turn the crank handle can vary depending on the weight of the load. For heavier loads, more force will be needed to start the lifting or pulling process.

However, thanks to the gear mechanism and the mechanical advantage it provides, the actual force required by the operator is much less than the weight of the load being moved.

This allows for precise control over the movement of the load, whether lifting, lowering, or pulling.

Key Features and Factors

The appeal of hand winches lies in their unique combination of features and factors that make them exceptionally versatile and reliable tools for a wide range of applications.

Let’s delve into these key features and factors in more detail to understand why hand winches are so valuable.

Lightweight and Portable

One of the most significant advantages of hand winches is their lightweight and portable nature. This makes them easy to transport and use in various locations, from construction sites to remote outdoor settings.

The ability to easily carry a hand winch means that tasks involving lifting, pulling, or tensioning can be accomplished more efficiently, without the need for heavy machinery or electrical power sources.

This portability is especially beneficial in situations where access is limited or where using larger equipment is impractical.

High Gear Ratios for Heavy Loads

Hand winches are designed with high gear ratios that allow them to lift or pull heavy loads with minimal effort.

The gear ratio is a measure of the mechanical advantage provided by the winch, indicating how many turns of the crank handle are needed to wind the cable a certain distance.

A higher gear ratio means that the winch can move a heavier load with each turn of the handle, albeit more slowly.

This feature is critical for applications where heavy lifting is required but where manual operation is preferred or necessary.

Overload Protections

Safety is paramount when handling heavy loads, and hand winches are equipped with overload protection mechanisms to ensure safe operation.

These protections can include shear pins that break if the load exceeds the winch’s capacity, preventing damage to the winch and injury to the operator.

Some models may also feature overload warning indicators or automatic braking systems that engage to prevent the winch from being used beyond its safe working load limit.

These safety features help to minimize the risk of accidents and ensure the longevity of the winch.

Corrosion-Resistant Metal Construction

Durability is another key factor that contributes to the appeal of hand winches. They are typically constructed from corrosion-resistant metals such as stainless steel or aluminum, which can withstand harsh environmental conditions without deteriorating.

This resistance to corrosion ensures that the winch remains functional and reliable over time, even when exposed to moisture, chemicals, or saltwater.

The robust construction of hand winches means they are a long-term investment for users who require a durable solution for lifting, pulling, or tensioning tasks.

Applications of Hand Winches

The diverse applications of hand winches stem from their adaptability, portability, and the mechanical advantage they offer, making them indispensable tools in various settings.

Here’s a closer look at the major areas where hand winches prove their worth:

Pulling or Positioning Lines, Wires, and Cables

Hand winches are invaluable for tasks that involve the precise pulling or positioning of lines, wires, and cables.

In construction and utility work, for example, winches are used to adjust the tension on electrical lines or to guide cables through conduits.

Their precise control allows for the careful handling of materials that require specific tension levels to function correctly or to be installed safely.

Lifting Equipment or Machinery

In industrial and manufacturing environments, hand winches facilitate the lifting of heavy equipment or machinery.

This application is crucial for maintenance tasks, where parts or entire machines need to be elevated for repairs or adjustments.

The manual operation of hand winches is especially useful in areas where electrical power is unavailable or in situations where the gentle handling of sensitive equipment is paramount.

Securing Loads on Vehicles

Hand winches are also employed to secure heavy loads on vehicles, ensuring safe transportation.

Whether it’s for hauling construction materials, machinery, or recreational vehicles, winches provide the necessary force to tighten straps or cables around the cargo.

This security is essential for preventing load shifting or loss during transit, minimizing the risk of accidents on the road.

Anchoring Boats and Barges

In maritime settings, hand winches play a vital role in anchoring boats and barges. They allow for the controlled release and retrieval of anchor lines, enabling vessels to be secured in position against currents or winds.

This application is not only critical for the safety of the vessels and their occupants but also for the protection of marine environments from potential damage.

Stretching Fences and Tents

Hand winches are also indispensable in agricultural and outdoor recreational activities, such as installing fences or setting up large tents.

They provide the necessary force to stretch fencing materials tight, ensuring they are secure and effective at containing livestock or marking boundaries.

Similarly, in setting up tents or shelters, winches help in achieving the tension required for stability and resistance against weather conditions.

Hunting and Fishing

In hunting and fishing, hand winches are used for a variety of tasks, including game retrieval and boat launching or docking.

They can significantly reduce the effort required to pull in large catches or to recover game from difficult terrain.

Additionally, hand winches assist in the careful placement or retrieval of boats, making them indispensable tools for sportsmen and outdoor enthusiasts.

Also check these Guides

- How to Install a Hand Winch on a Trailer

- How to Safely Attach a Hand Winch to a Tree or Post

- A Step-by-Step Guide to Releasing a Hand Winch

- Building a Hand Crank Winch at Home

- How to Safely and Effectively Use a Hand Winch

- How to Securely Attach Cable to a Hand Winch

Conclusion

Hand winches are simple yet powerful devices that can make a significant difference in how we lift, pull, and tension loads.

Whether you’re a professional working on a construction site, a hobbyist setting up camp, or someone securing loads on a vehicle, understanding how a hand winch works and its applications can help you choose the right winch for your needs.

With its combination of portability, strength, and versatility, the hand winch is indeed a tool worth having in your toolkit.