Releasing a come along winch is an essential skill that requires careful attention to detail to ensure safety and prevent damage.

Whether you’re a DIY enthusiast, a construction worker, or someone involved in heavy lifting, understanding the proper way to release tension from a winch can be a game-changer.

Let’s dive into the process and make sure you’re equipped with the knowledge to handle this task with confidence.

Inspect the Winch Components

Before releasing tension, inspect the key components of the come along winch:

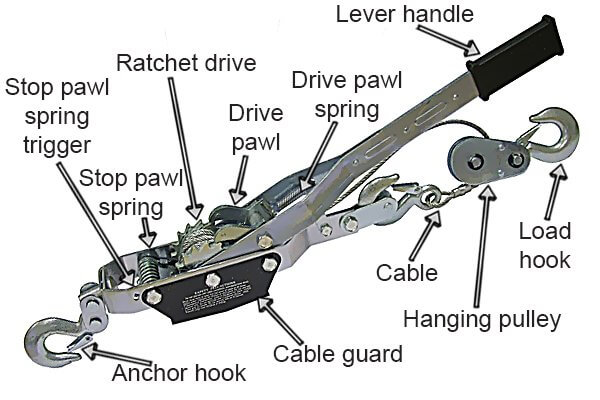

- Ratchet: Check for damaged or worn out teeth that may slip. Ensure pawl engages correctly.

- Cable: Look for any kinks, frays, or damage. Make sure it’s rated for the winch capacity.

- Frame and gears: Inspect for cracks or leaks indicating damage. Gears should be in good condition.

Also note which direction the cable is pulling so you can stand clear while releasing.

Also check: Best come along winches 2024

Prepare to Release

Preparing to release the tension from a come-along winch is a critical step that demands your full attention to safety and precaution.

This stage is all about setting up a safe environment to prevent any accidents or injuries that might occur due to sudden movements or mishandling of the equipment. Let’s delve deeper into this crucial phase.

Clearing the Area

The space around the winch and the load it’s attached to needs to be completely clear. This means removing any unnecessary equipment, tools, or debris that could pose a tripping hazard or obstruct the operation.

The idea is to create a safe perimeter around the work area.

This not only ensures your safety but also makes the task of releasing the winch smoother and easier, with fewer obstacles in the way.

Ensuring No One is Nearby

It’s imperative to make sure that no one is standing close to the winch or the load, and especially that no one is holding onto the cable.

When tension is released, the cable can snap back or move unexpectedly. If someone is in the path of the cable or too close to the load, they could be struck by the cable or injured by shifting equipment.

Always double-check the surroundings and verbally confirm with your team that the area is clear before proceeding.

Wearing Protective Gloves

The importance of wearing gloves cannot be overstressed. The cable on a come-along winch can be rough, and handling it without protection could lead to cuts, abrasions, or even more severe hand injuries.

Gloves also provide a better grip on the winch handle and any other components you might need to adjust during the release process.

Choose gloves that are durable yet allow for flexibility and a good grip.

Why This Step Matters

The preparation phase sets the stage for a safe and controlled release of the winch. Skipping this step or rushing through it increases the risk of accidents, potentially leading to injuries or damage to the load you’re working with.

It’s a fundamental part of the process that ensures the safety of you and those around you, as well as the integrity of the load and equipment.

Loosen Ratchet Dogs

Loosening the ratchet dogs on a come-along winch is a pivotal step in safely releasing the tension.

This process involves interacting directly with the winch’s internal mechanisms, specifically the ratchet and pawl system, which are designed to maintain tension on the cable and prevent it from unwinding unintentionally.

Let’s delve deeper into this critical step to ensure you can perform it with confidence and safety.

Understanding the Mechanism

The ratchet and pawl mechanism is at the heart of a come-along winch’s operation. The ratchet is a wheel or bar with teeth, over which the pawl (a pivoting catch) engages to allow movement in one direction while preventing it in the opposite direction.

This mechanism is what holds the tension on the cable and allows the winch to pull or lift loads.

Locating the Ratchet Release

The first step in loosening the ratchet dogs is to locate the ratchet release or control mechanism on your winch. This is usually a lever or button located near the handle or the ratchet and pawl mechanism itself.

Its primary function is to disengage the pawl from the ratchet teeth, allowing the ratchet to turn freely in both directions.

Disengaging the Pawl

Once you’ve located the ratchet release, the next step is to disengage the pawl. This might require pressing down on a lever, pushing a button, or in some cases, manually moving the pawl away from the ratchet teeth.

The exact method depends on the design of your come-along winch. It’s important to perform this action gently but firmly to ensure that the pawl is completely disengaged.

If the pawl is not fully disengaged, the ratchet might not turn freely, making it difficult to safely release the tension.

Importance of Smooth Transition

The reason why disengaging the pawl carefully is so crucial is that it ensures a smooth transition into the tension release phase.

If the pawl were to engage with the ratchet teeth unexpectedly while you’re trying to release the tension, it could cause the winch to jerk or suddenly stop.

This not only poses a risk of damaging the winch or the load but can also lead to serious injuries if the operator is caught off guard.

Safety Precautions

When performing this step, it’s vital to maintain a firm grip on the winch handle or control mechanism to manage the tension release effectively.

Unexpected movements can occur if the tension on the cable is high. Always stand clear of the direct line of the cable and ensure that no part of your body is in a position where it could be injured if the cable were to snap back or if the load were to shift suddenly.

Relieve Tension Slowly

Relieving tension slowly from a come-along winch is a delicate operation that requires precision, patience, and a steady hand.

Once the ratchet mechanism is disengaged, and the pawl is no longer locking the gear, you’re ready to carefully manage the release of tension.

This step is crucial for maintaining control over the load and ensuring safety. Let’s break down the process and the considerations involved in greater detail.

Gradual Turning of the Handle

The process begins with a gradual turning of the winch handle. This action should be slow and controlled.

The idea is to release the tension bit by bit, preventing any sudden movements that could destabilize the load or cause the winch to recoil unexpectedly.

A slow release ensures that you can stop immediately if something doesn’t seem right, such as the load shifting in an unsafe manner or the cable showing signs of undue stress.

Maintaining Control

Keeping tension under control is paramount. This means constantly feeling the resistance on the winch handle and adjusting your force accordingly.

If the tension decreases too quickly, it could indicate a problem, such as the cable slipping or the load moving unpredictably.

On the other hand, if the tension seems not to be easing, the mechanism might not be fully disengaged, or there could be an obstruction. In either case, pause and reassess the situation.

Handling Dual Gear Models

Dual gear models of come-along winches add an extra layer of complexity to the tension release process. These models can release tension from both directions, depending on the load and how the tension was initially applied.

It’s crucial to understand the specific operation of your winch model. In some cases, you may need to alternate between gears to release the tension evenly and safely.

Always refer to the manufacturer’s instructions for guidance on handling your specific model.

Watching the Cable

As you release the tension, keep a watchful eye on the cable. It should gradually coil back onto the drum, but this needs to be a smooth process.

Any jerking, snagging, or uneven winding of the cable requires immediate attention. Pause the tension release and address any issues before continuing.

This might involve manually guiding the cable (with gloves on for safety) to ensure it winds correctly.

The Importance of Patience

The key to successfully relieving tension slowly is patience. Rushing this process increases the risk of accidents, equipment damage, and personal injury.

Each movement should be deliberate and well-considered, with constant awareness of the winch, the load, and the cable’s behavior.

Allow Cable to Recoil

Allowing the cable to recoil onto the drum of a come-along winch is a critical phase in the process of releasing tension.

This step ensures that the cable is safely and efficiently wound back onto the drum, maintaining the integrity of the equipment and preventing potential hazards.

Here, we delve into the nuances of this process, providing a detailed explanation to guide you through this crucial task.

Understanding Cable Recoil

As tension is slowly released from the come-along winch, the cable begins to recoil or retract back onto the drum.

This recoil is a natural consequence of the tension easing and the cable seeking to return to its resting state on the drum.

The process needs to be managed carefully to ensure that the cable winds correctly and does not become tangled, kinked, or damaged.

Step-by-Step Guidance

- Maintain a Safe Distance: Always keep your hands and other body parts away from the recoiling cable. The cable can move unpredictably, and if it were to snap back or whip, it could cause serious injury.

- Guide the Cable: Use a tool or a piece of wood to guide the cable back onto the drum if necessary. This can help prevent kinks and ensure that the cable winds evenly across the drum. Never use your hands directly on the cable during recoil.

- Monitor the Recoil Speed: Pay attention to how quickly the cable recoils. The speed should correlate with how slowly you’re releasing the tension via the winch handle. If the cable begins to recoil too quickly, it may indicate that too much tension was released too fast. In such cases, pause and reassess your approach.

- Address Snags Immediately: If the cable snags or does not wind properly, stop the recoil process immediately. Correct any issues before continuing. Snags can lead to damage to the cable or the winch and potentially create a safety hazard.

- Ensure Even Winding: Aim for the cable to lay flat and even across the drum. Uneven layers or coils can lead to problems the next time the winch is used, including potential jamming or damage to the cable.

The Importance of Controlled Recoil

Controlled recoil is not just about preventing injury; it’s also crucial for maintaining the longevity and functionality of the winch.

A well-maintained cable and drum mechanism are essential for the safe and effective operation of a come-along winch. Cables that are improperly wound or damaged can compromise the winch’s performance and safety.

Secure Winch Components

Securing the winch components after releasing the tension and recoiling the cable is a critical step to ensure the safety and readiness of your come-along winch for future use.

This stage involves re-engaging the locking mechanisms and organizing the cable on the drum to prevent accidental release or damage.

Here’s a closer look at how to effectively secure your winch components.

Engage the Pawl

- Understanding the Pawl’s Role: The pawl is a crucial safety feature in the come-along winch mechanism. It engages with the ratchet wheel to prevent the gear from turning backward, thereby locking the tension in place when the winch is in use and ensuring it remains stationary when not in use.

- Re-engaging the Pawl: After the cable has been fully recoiled onto the drum, you need to manually re-engage the pawl with the ratchet. This might require you to move the pawl into position against the ratchet wheel, ensuring it’s securely in place. In some models, this may happen automatically when you stop turning the handle, but it’s always good practice to check.

Install a Cable Stop

- Purpose of a Cable Stop: A cable stop is a device or mechanism used to fix the end of the cable to the drum, preventing it from becoming unwound or tangled when not in use. It helps maintain tension on the outer layer of the cable, keeping it neatly organized and ready for the next use.

- Installing the Cable Stop: Depending on the design of your winch, installing a cable stop may involve threading the end of the cable through a designated slot or hole on the drum and securing it in place with a clamp or knot. Ensure that the stop is firmly secured to prevent the cable from slipping out.

Check the Cable Layers

- Even Distribution: After securing the cable stop, take a moment to inspect the layers of cable on the drum. They should be evenly distributed across the width of the drum to prevent overlaps or gaps that could lead to kinks or jams the next time the winch is used.

- Adjust if Necessary: If you notice any unevenness in the cable layers, you may need to manually adjust them. This can be done by slightly unwinding and then carefully rewinding the cable under controlled tension to achieve a neat and even layering.

Final Inspection

- Assess the Winch: With the pawl engaged and the cable stop in place, give your winch a final once-over. Ensure that all components are secure, and there’s no loose or damaged parts. This is also a good time to lubricate any moving parts according to the manufacturer’s recommendations to keep the winch in good working condition.

- Test the Locking Mechanism: Gently pull on the cable to test the pawl’s engagement with the ratchet. The mechanism should hold firm and prevent the cable from unwinding. If there’s any slip, re-check the engagement and ensure everything is correctly positioned and secure.

Inspect Winch After Use

Inspecting your come-along winch after use is an essential part of the maintenance routine that ensures the tool remains in good working condition and is safe for future operations.

This detailed inspection helps identify any wear, damage, or malfunction that might have occurred during use, allowing for timely repairs or adjustments.

Here’s a step-by-step guide to effectively inspect your winch after use.

Visual Inspection

- Examine the Cable: Look for any signs of fraying, kinks, or wear on the cable. The integrity of the cable is crucial for safe winch operation. Damaged cables pose a significant safety risk and must be replaced before the winch is used again.

- Check the Winch Body: Inspect the body of the winch for any cracks, bends, or corrosion. Pay special attention to the areas around the mounting points, as these are under significant stress during operation.

- Inspect the Ratchet and Pawl: Ensure that the ratchet and pawl mechanism is functioning correctly. Look for signs of wear or damage on the teeth of the ratchet and the pawl. These components are vital for the winch’s locking mechanism, and any compromise could result in failure during use.

Functional Testing

- Test the Ratchet Mechanism: Engage and disengage the ratchet mechanism to ensure it operates smoothly and locks securely. This test can help identify issues with the pawl engagement or spring tension that might not be obvious during a visual inspection.

- Operate the Winch: Gently operate the winch handle to ensure that the gears are moving smoothly and that there’s no unusual resistance or noise. This can help pinpoint issues with the internal gears or lubrication.

Check for Lubrication

- Lubricate Moving Parts: After cleaning any dirt or debris from the winch, apply lubricant to the moving parts according to the manufacturer’s recommendations. Proper lubrication reduces wear and ensures smooth operation.

- Inspect for Adequate Lubrication: Ensure that all necessary components, including gears, the cable drum, and the ratchet mechanism, are adequately lubricated. Over time, lubrication can dry out or become contaminated with dirt, reducing its effectiveness.

Assess for Replacement or Repair

- Identify Parts that Need Replacement: If any components are found to be damaged or excessively worn, they should be marked for replacement. Using a winch with damaged parts can be dangerous and lead to failure under load.

- Schedule Repairs: For any issues that cannot be resolved through simple maintenance or part replacements, schedule repairs with a qualified technician. This is especially important for any structural issues with the winch body or problems with the winch mechanism that could affect performance and safety.

Record Keeping

- Maintenance Log: Keep a record of your inspection findings and any maintenance performed on the winch. This log can be invaluable for tracking the winch’s condition over time and planning for regular maintenance or replacements before failures occur.

Key Takeaways

Releasing a come along winch safely involves a series of careful steps, from inspection to the final recoil of the cable. Remember to prioritize safety by clearing the area, wearing protective gear, and handling the winch and cable with caution.

By following these guidelines, you can ensure a smooth and safe process, preserving both your equipment and well-being.

Keep these steps in mind, and you’ll be well-prepared to handle your come along winch with expertise and confidence.