Hey there! If you’re looking to install or repair a winch solenoid, you’ve come to the right place.

In this guide, I’ll walk you through everything you need to know about winch solenoid wiring, from understanding its purpose to ensuring a safe and efficient setup. Let’s dive in!

Quick Overview

- Prepare the Wires and Connectors: Strip wire ends and attach connectors securely.

- Connect the Battery Cable to the Solenoid: Attach the power wire from the battery to the solenoid.

- Ground the Solenoid: Connect the ground wire from the solenoid to the vehicle chassis.

- Wire the Control Cables: Attach control wires from the switch or remote to the solenoid.

- Connect the Solenoid to the Winch Motor: Secure the power wire from the solenoid to the winch motor.

Tools and Materials Needed

Before we start, make sure you have the following tools and materials:

Tools:

- Welding equipment (MIG or TIG welder, welding gloves, and mask)

- Angle grinder or cutting torch

- Wrenches and sockets

- Drill and drill bits

- Clamps

- Measuring tape

- Marker or soap stone

Materials:

- Steel tubing (typically 2-3 inches in diameter, thickness depending on weight capacity needs)

- Steel plate for winch mounting

- D-rings or recovery points

- Hardware (nuts, bolts, washers)

- Optional: Lights, skid plates, or other accessories

Safety Gear:

- Welding helmet or face shield

- Fire-resistant clothing

- Gloves

- Safety glasses

Also check: Best Winch Solenoid

How to Wire a Winch Solenoid: Step-by-Step Wiring Instructions

Step 1: Prepare the Wires and Connectors

First, you need to prepare the wires and connectors.

Start by cutting the wires to the appropriate lengths.

Make sure they can reach from the battery to the solenoid and from the solenoid to the winch motor without being too tight or too loose.

Next, strip the insulation off the ends of each wire using wire strippers.

You want to expose about an inch of the bare wire.

Be careful not to nick the wire strands, as this can weaken the connection.

Now, it’s time to attach the connectors. Slide the connectors over the bare ends of the wires and use crimpers to secure them in place.

Make sure the connectors are tightly crimped so they won’t come loose. A good connection is essential for preventing electrical issues down the line.

Step 2: Connect the Battery Cable to the Solenoid

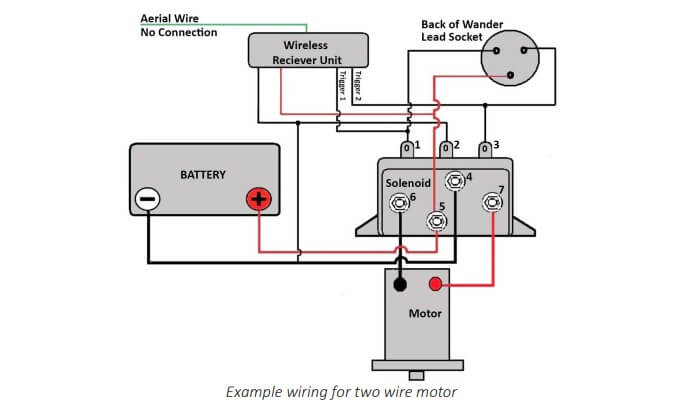

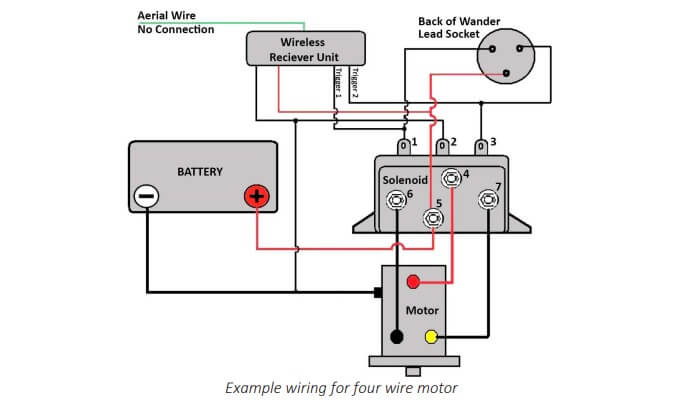

With your wires and connectors prepared, you can start connecting them to the solenoid.

Begin with the battery cable. This is a thick power wire that carries electricity from the battery to the solenoid.

Attach one end of the power wire to the positive terminal of the battery.

Use a wrench to tighten the terminal nut securely, but don’t overtighten as this could damage the battery post.

Next, connect the other end of the power wire to the appropriate terminal on the solenoid.

This terminal is usually marked with a “+” sign or labeled as the power input. Again, ensure the connection is tight and secure.

Step 3: Connect the Ground Cable to the Solenoid and Vehicle Chassis

The next step is to connect the ground cable. This wire completes the electrical circuit by connecting the solenoid to the vehicle’s chassis.

Start by attaching one end of the ground wire to the solenoid’s ground terminal.

This terminal is usually marked with a “-” sign or labeled as the ground.

Then, connect the other end of the ground wire to a clean, bare metal spot on the vehicle chassis.

You might need to use a wrench to remove any paint or corrosion from the connection point to ensure a good ground connection. Tighten the connection securely.

Step 4: Wire the Control Cables (Switch or Remote)

Now it’s time to wire the control cables. These smaller wires connect the solenoid to the switch or remote control that you use to operate the winch.

Connect the control wires from the switch or remote control to the solenoid’s control terminals.

These terminals are often color-coded to match the wires, making it easier to connect them correctly.

Ensure each wire is attached to the right terminal, as specified in your winch’s wiring diagram.

Step 5: Connect the Solenoid to the Winch Motor

Finally, you need to connect the solenoid to the winch motor. This involves attaching a power wire from the solenoid to the winch motor’s positive terminal.

Start by connecting one end of the power wire to the appropriate terminal on the solenoid.

This terminal is typically labeled for the winch motor output.

Then, connect the other end of the power wire to the positive terminal on the winch motor.

Make sure this connection is tight and secure to ensure reliable operation.

Safety Precautions

Safety first! Here are some crucial safety tips to follow:

- Disconnect the Battery: Always disconnect the battery before starting any wiring work to prevent accidental shocks or short circuits.

- Proper Cable Routing: Ensure cables are routed away from sharp edges, heat sources, and moving parts to avoid damage.

- Insulation: Use electrical tape to insulate all connections and prevent short circuits.

- Avoid Hazards: Be aware of potential hazards such as electrical shorts and ensure all connections are secure and insulated.

Troubleshooting Tips

Even with careful installation, issues can arise with your winch solenoid wiring. Here are some common problems you might encounter and their solutions:

Winch Not Working

If your winch is not working at all, here are a few steps to troubleshoot the issue:

- Check All Connections:

- Ensure all the electrical connections are tight and secure. Loose connections can prevent the necessary current from reaching the winch motor.

- Inspect each connection point from the battery, solenoid, ground, and winch motor. Make sure the terminals are clean and free from corrosion.

- Battery Charge:

- Verify that your battery is fully charged. A weak or dead battery will not provide enough power for the winch to operate.

- Use a multimeter to check the battery voltage. A fully charged battery should read around 12.6 to 12.8 volts. If it’s lower, consider recharging or replacing the battery.

- Inspect the Fuses:

- Check the fuse in the winch circuit. A blown fuse can interrupt the power supply. Replace any blown fuses with the correct type and rating.

- Check the Solenoid:

- Test the solenoid to ensure it’s functioning properly. You can do this by listening for a clicking sound when you activate the winch. If there’s no click, the solenoid might be faulty.

Intermittent Operation

If your winch operates sporadically or intermittently, here’s what to check:

- Inspect Control Wires:

- Look for any signs of damage on the control wires, such as fraying, cuts, or burns. Damaged wires can cause intermittent connections.

- Ensure the control wires are securely connected to both the switch or remote and the solenoid. Loose connections can lead to inconsistent operation.

- Check for Corrosion:

- Corrosion on the terminals or connectors can disrupt the electrical flow. Clean any corrosion with a wire brush and apply dielectric grease to prevent future corrosion.

- Examine the Switch or Remote:

- Test the switch or remote control for faults. If the switch is not making proper contact, it can cause intermittent operation. Replace the switch if it’s faulty.

Solenoid Clicking but Winch Not Running

If you hear the solenoid clicking but the winch motor doesn’t run, consider these steps:

- Check the Battery:

- Even if the battery is providing some power, it might not be enough to turn the winch motor. Test the battery voltage under load (while trying to operate the winch). If the voltage drops significantly, the battery might be weak and need replacing.

- Inspect the Solenoid:

- A clicking solenoid indicates it’s receiving a signal from the switch, but it doesn’t necessarily mean it’s allowing power through to the winch motor. Test the solenoid with a multimeter to ensure it’s working correctly. If the solenoid is faulty, replace it.

- Check the Motor Connections:

- Ensure the power cable from the solenoid to the winch motor is securely connected. A loose connection can prevent the motor from receiving sufficient power.

- Test the Winch Motor:

- Directly connect the winch motor to a power source to test if it runs. If the motor doesn’t run when directly powered, the problem lies within the motor itself, and it may need to be serviced or replaced.

Maintenance and Care

To keep your winch solenoid in top shape, regular maintenance is key:

- Inspect Connections: Periodically check all wiring connections for corrosion or looseness.

- Clean Terminals: Clean battery and solenoid terminals to ensure good electrical contact.

- Protect Wiring: Use zip ties and protective covers to keep wires secure and shielded from the elements.

Also check: how to wire a winch without a solenoid

Conclusion

In summary, wiring a winch solenoid may seem daunting, but with the right tools, materials, and instructions, you can do it successfully.

Follow these steps carefully, prioritize safety, and you’ll have a reliable winch system ready to tackle any heavy lifting. Happy winching!