A winch solenoid is a heavy-duty relay switch that controls the electrical current between your vehicle’s battery and the winch motor. It engages only when the winch switch is activated, allowing high current to flow without damaging the wiring or switch.

This guide explains how winch solenoids work, where they’re used, and why they’re essential for safe, responsive winching in off-road, trailer, and utility applications.

What is a Winch Solenoid? Detailed Breakdown

A winch solenoid is an electromagnetic switch designed to control the operation of a winch. It consists of several key components: a coil of wire, an iron core, and a plunger.

When electrical current flows through the coil, it creates a magnetic field that moves the plunger and activates the winch.

To understand it better, let’s examine its components, construction, and different types.

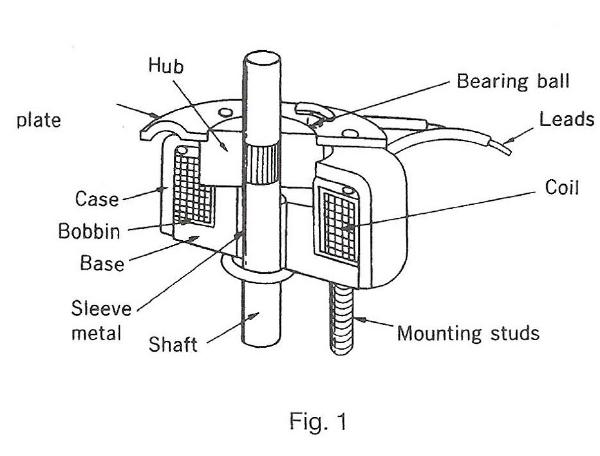

Basic Components and Construction

A winch solenoid typically consists of the following key components:

Coil of Wire

This is the heart of the solenoid. The coil is usually made of copper wire, wound tightly around a cylindrical core. When electrical current passes through the coil, it generates a magnetic field.

Iron Core

Also known as the armature, the iron core is located inside the coil. The magnetic field generated by the coil pulls the iron core towards it.

Plunger

The plunger is a movable part connected to the iron core. When the magnetic field pulls the iron core, the plunger moves as well, activating the winch mechanism.

Contacts

These are the electrical connection points within the solenoid. When the plunger moves, it closes the circuit by bringing the contacts together, allowing electrical current to flow to the winch motor.

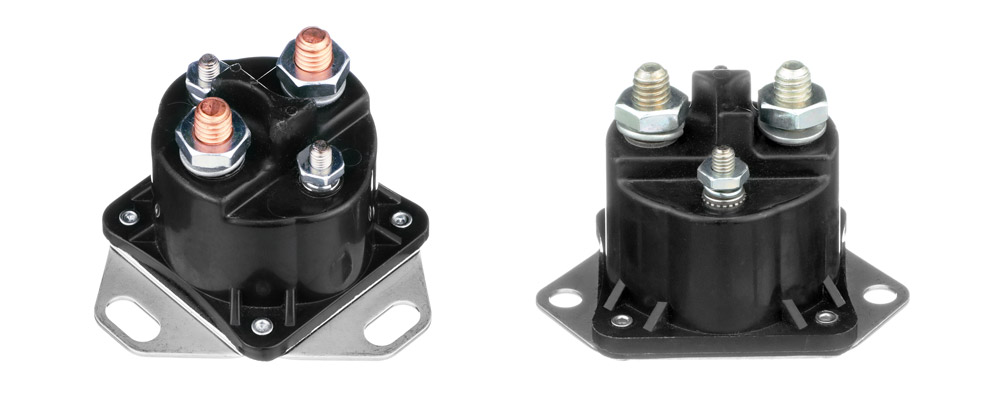

Housing

A solenoid’s housing is typically made of durable materials like steel or plastic, protecting the internal components from dust, moisture, and physical damage.

Difference Between Winch Solenoid and Regular Solenoid

While both winch solenoids and regular solenoids operate on similar principles, there are some key differences:

Purpose

Regular solenoids are used for various applications like doorbells, valves, and basic mechanical movements. Winch solenoids, on the other hand, are specifically designed for heavy-duty tasks such as winching and lifting.

Construction

Winch solenoids are built to withstand higher currents and more demanding conditions. They are generally more robust, with thicker coils and stronger plunger mechanisms.

Functionality

Regular solenoids may have simpler on/off functions, while winch solenoids often have more complex control systems to manage the power needed for winching operations.

Types of Winch Solenoids

Winch solenoids come in different types, each designed for specific uses:

Linear Solenoid

These solenoids move the plunger in a straight line. They are commonly used in applications where linear motion is required, such as in door locks and automotive starters.

Rotary Solenoids

In these solenoids, the plunger moves in a rotational manner. They are used in applications where a rotational movement is needed, like in certain types of valves and actuators.

Continuous Duty Solenoids

These are designed to handle continuous operation without overheating. They are often used in applications where the solenoid needs to remain active for extended periods.

Intermittent Duty Solenoids

These solenoids are meant for short, high-power bursts and need cooling periods between operations.

They are typically used in applications where the solenoid is activated occasionally, such as in winches used for off-road vehicles.

How Does a Winch Solenoid Work?

The operation of a winch solenoid relies on the principles of electromagnetic induction. This process transforms electrical energy into mechanical motion, enabling the winch to pull or lift heavy loads.

Let’s dive deeper into each step and the factors influencing the performance of a winch solenoid.

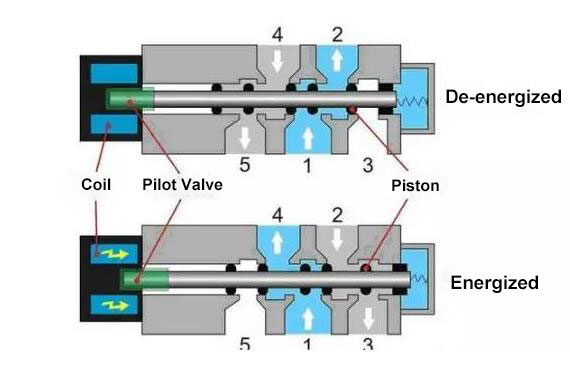

Step-by-Step Explanation of the Working Mechanism

Activation: When you activate the winch using a switch or remote control, electrical current from the power source flows to the solenoid. This power source is typically a battery, especially in automotive applications.

Coil Energization: As the current flows through the solenoid’s coil, it creates a magnetic field around the coil. The strength of this magnetic field depends on the amount of current and the number of turns in the coil.

Magnetic Attraction: The magnetic field generated by the coil pulls the iron core (plunger) towards the center of the coil. This movement is due to the magnetic attraction between the magnetic field and the iron core.

Circuit Completion: As the plunger moves, it bridges the contacts within the solenoid, closing the electrical circuit. This action allows the current to flow from the battery to the winch motor.

Motor Activation: With the circuit closed, the current energizes the winch motor. The motor then converts electrical energy into mechanical energy, which powers the winch mechanism to pull or lift the load.

Load Operation: The winch motor, now powered, engages the winch drum and cable, pulling or lifting the attached load.

When the load reaches the desired position, releasing the winch control stops the current flow, deactivating the solenoid and motor.

Factors Affecting Performance

Several factors influence a winch solenoid’s performance:

Voltage and Current: Higher voltage boosts the magnetic field strength but can cause overheating if too high.

Coil Design: More turns in the coil produce a stronger magnetic field but increase resistance.

Quality of Connections: Clean, secure connections prevent voltage drops and ensure efficient operation.

Material and Construction: High-quality materials enhance durability and performance.

Environmental Factors: Extreme temperatures and humidity can affect the solenoid’s performance.

Selection and Installation Considerations

Choosing the right winch solenoid and installing it properly are critical to ensure your winch operates smoothly and safely.

Let’s delve into the key factors you need to consider and the best practices for installation and maintenance.

Selection Criteria

Size: Ensure the solenoid fits the available space. Measure dimensions to avoid compatibility issues.

Voltage: Match the solenoid’s voltage rating with the winch’s power source for optimal performance and to prevent damage.

Duty Cycle: Choose a solenoid with a duty cycle that suits your usage frequency and duration.

Current Rating: Ensure the solenoid can handle the required current without overheating.

Environmental Rating: Select a solenoid with suitable protection ratings (e.g., IP ratings) for exposure to moisture, dust, or extreme temperatures.

Installation Practices

Secure Mounting: Install the solenoid in a stable position to prevent vibrations that could loosen connections or damage components. Use sturdy brackets and bolts.

Correct Wiring: Follow the manufacturer’s wiring diagram to connect the solenoid correctly. Ensure all wires are securely fastened and insulated to prevent short circuits.

Regular Inspections: Check connections regularly for signs of wear, corrosion, or loose components. Tighten any loose connections and clean any corroded parts.

Safety Guidelines

- De-energize Before Handling

- Use Protective Gear

- Follow Manufacturer’s Instructions

Troubleshooting and Maintenance

Common Issues and Solutions

No Power

If the solenoid is not receiving power, check the power supply and all connections. Ensure the battery is charged and that there are no broken wires or loose connections.

Overheating

Overheating can be caused by prolonged use or insufficient ventilation. Allow the solenoid to cool down and ensure it has adequate airflow. Avoid using it continuously for extended periods beyond its duty cycle.

Sticking Plunger

A sticking plunger can prevent the solenoid from operating correctly. Clean any debris from the solenoid and lubricate the plunger with a suitable lubricant

Preventive Maintenance Tips

Regular Inspections: Check for wear, damage, or corrosion.

Functional Testing: Test regularly for proper operation.

Lubrication: Keep moving parts well-lubricated.

Replace Worn Parts: Address any worn or damaged components promptly.

Advantages and Disadvantages

Advantages

- Compact Size: They fit into tight spaces.

- High Force Output: They can exert significant force.

- Reliability: They are durable and dependable.

Disadvantages

- Power Consumption: They require a lot of power.

- Heat Generation: They can overheat with continuous use.

- Limited Stroke Length: The range of motion is often short.

Also Check

- Best Winch Solenoid

- How to Wire a Winch Solenoid

- Wiring a Winch Without a Solenoid

- How to Test and Replace Winch Solenoid

Conclusion

Winch solenoids are essential components in many machines and devices, providing the power and control needed for heavy-duty tasks.

Their versatility makes them invaluable in automotive, industrial, and recreational applications. By understanding how they work and how to maintain them, you can ensure they perform reliably and safely.

Continue exploring and learning about these fascinating devices to make the most of their capabilities.