Discover what a winch plate is, its essential role in various applications, and gain insights into the mechanics behind its operation.

Learn how this crucial component facilitates efficient load handling and movement.

What is a Winch Mounting Plate?

A winch plate is a sturdy metal plate, typically made of steel or aluminum, designed to be mounted on a vehicle, equipment, or structure.

It features a slot or opening through which the winch line or cable can pass, allowing for a direct and efficient connection between the winch and the load being pulled or lifted.

The primary purpose of a winch plate is to distribute the immense forces generated during winching operations evenly across a larger surface area.

This distribution of force helps prevent damage to the mounting surface and ensures a secure anchor point for the winch line.

Components and Materials

The construction of a winch plate involves several key components, each contributing to its overall functionality:

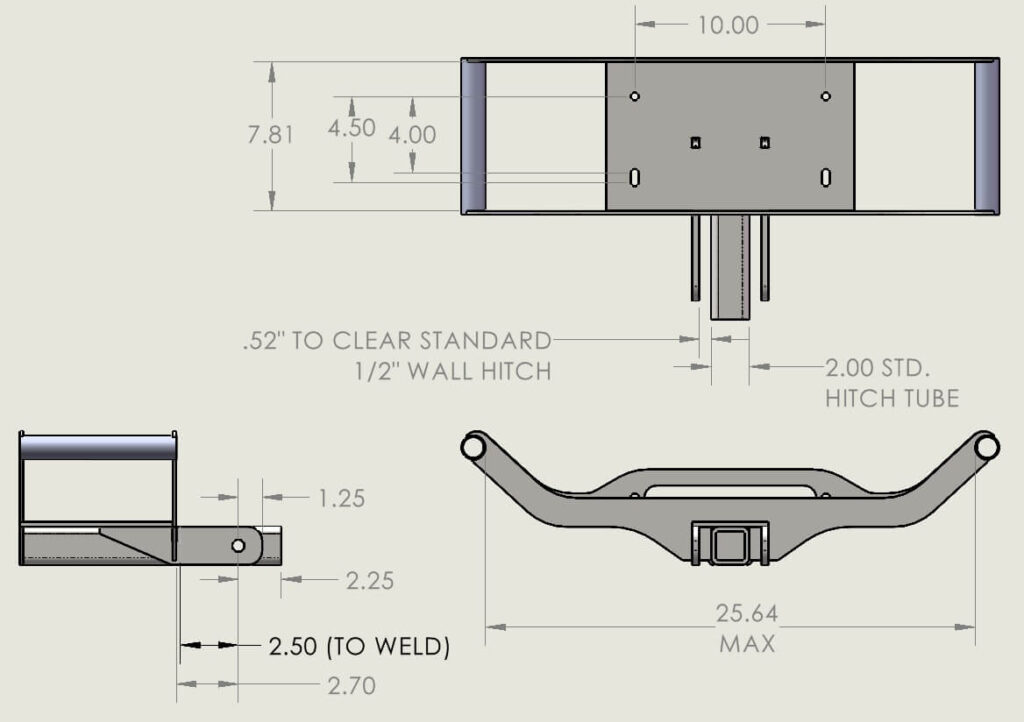

Base Plate: The primary body of the winch plate, providing the main surface for mounting the winch.

Mounting Holes: Precision-drilled holes that allow for secure attachment to a vehicle or structure, ensuring the winch remains firmly in place during operation.

Bolt Patterns: Specific configurations of bolt holes that match various winch models, facilitate easy installation and compatibility.

Reinforcing Ribs: Additional support structures are integrated into the design to enhance strength and prevent bending or deformation under heavy loads.

Fairleads: Guide components that help direct the cable smoothly onto the winch drum, reducing wear and ensuring efficient operation.

Materials used in winch plate construction are chosen for their specific properties:

Steel: Known for its robustness and high load-bearing capacity, steel winch plates are ideal for heavy-duty applications where maximum strength is required.

Aluminum: Favored for its lighter weight and resistance to corrosion, aluminum winch plates are perfect for environments where reducing overall weight is crucial, such as in off-road vehicles or marine settings.

Variations

Winch plates vary significantly based on their intended use and the specific requirements of the task at hand. Some common variations include:

Size:

Winch plates range from small, compact designs suitable for light-duty tasks to larger, more robust versions capable of handling heavy-duty operations.

Capacity:

Depending on the strength of the materials and the design, winch plates can support different load capacities.

It’s essential to choose a winch plate that matches the expected load to ensure safety and efficiency.

Design:

The design of a winch plate can be tailored to specific applications.

For instance, winch plates for off-road vehicles often feature compact, lightweight designs for easy portability, while industrial winch plates may include additional reinforcement to handle extreme loads.

Purpose and Applications

Winch plates are essential for lifting and pulling heavy loads, making them indispensable in many industries.

Lifting and Pulling Heavy Loads

The primary function of a winch plate is to provide a secure mounting point for a winch, enabling it to lift or pull heavy objects.

This capability is crucial in situations where manual lifting would be impractical or dangerous.

Industrial and Automotive Uses

In construction, winch plates are used with cranes and hoists to move heavy materials. In manufacturing, they help transport large components across the factory floor.

In the automotive industry, winch plates are essential for tow trucks and recovery vehicles, providing the necessary support to recover stranded vehicles.

Marine and Other Industries

Winch plates are also used in the marine industry to secure anchors and other heavy equipment.

Their versatility makes them valuable in many other fields, including forestry, mining, and entertainment, where lifting and pulling tasks are common.

How a Winch Plate Works

Understanding how a winch plate works involves delving into the mechanical principles and components that enable it to lift and pull heavy loads efficiently. Let’s break down the process in more detail.

Mechanical Principles

The primary role of a winch plate is to provide a secure and stable mounting point for a winch.

The winch itself is a mechanical device that exerts force on a cable or rope wound around its drum, allowing it to move heavy objects. Here’s how the process works:

Mounting the Winch:

The winch is bolted onto the winch plate, which is then attached to a stable surface, such as a vehicle frame or a fixed structure. This ensures that the winch remains stationary while in use.

Applying Force:

When the winch is activated, either manually or through a power source (electric or hydraulic), it begins to pull the cable or rope.

The force applied by the winch is directed through the cable, allowing it to lift or pull heavy loads.

Mechanical Advantage:

The gears within the winch play a crucial role by providing mechanical advantage.

This means that a small input force applied to the winch handle or motor is multiplied, resulting in a much larger output force.

This mechanical advantage is what enables the winch to move heavy loads with relatively little effort from the operator.

Role of Gears, Drums, and Cables

Several components work together within the winch system to ensure efficient operation:

Gears:

The gears within the winch are responsible for converting the input force into a greater output force.

Different gear ratios can be used to achieve varying levels of mechanical advantage.

For example, a higher gear ratio means more force is exerted on the cable, allowing the winch to lift heavier loads.

Drum:

The drum is a cylindrical component around which the cable or rope is wound.

As the winch operates, the drum rotates, either winding in or paying out the cable.

The size and capacity of the drum determine how much cable can be stored and how smoothly the cable is handled.

Cable or Rope:

The cable or rope is the medium through which the force is transmitted from the winch to the load.

The material and condition of the cable are critical for safe operation.

Steel cables are common for their strength, while synthetic ropes are favored for their lighter weight and flexibility.

Efficiency and Load Capacity

The efficiency and load capacity of a winch plate and winch system depend on several factors:

Material Quality:

High-quality materials used in the construction of the winch plate and winch components ensure durability and reliability.

For example, using high-strength steel or aluminum can significantly impact the system’s performance.

Design:

The design of the winch plate and the winch itself affects their efficiency.

Well-designed components that fit together seamlessly reduce friction and wear, enhancing overall efficiency.

Proper Installation:

Correct installation is crucial for the system’s efficiency. The winch plate must be securely mounted, and the winch properly aligned to ensure that the force is applied evenly and effectively.

Load Capacity:

The load capacity is determined by the specifications of the winch and the winch plate.

It’s important to adhere to these specifications to avoid overloading the system, which can lead to equipment failure and safety hazards.

Types of Winch Plates

Winch plates can be classified based on their power source and portability.

Power Source

Hydraulic Winch Plates:

Powered by hydraulic systems, these are commonly used in heavy-duty industrial applications due to their high power and reliability.

Electric Winch Plates:

These are convenient and easy to install, making them popular for automotive and recreational use.

Manual Winch Plates:

Operated by hand, these are suitable for lighter tasks and situations where power sources are unavailable.

Portability

Portable Winch Plates:

Lightweight and easy to transport, these are ideal for off-road adventures and temporary setups.

Fixed Winch Plates:

Permanently mounted, these are used in industrial settings where stability and durability are crucial.

Specialized Winch Plates

Some winch plates are designed for specific applications, such as those used in marine environments, which are made to withstand corrosive conditions, or those in forestry, which are designed for rugged use.

Do I Need a Winch Mounting Plate

Yes, you need a winch mounting plate if you want to securely attach a winch to your vehicle. Here are a few reasons why:

- Stability and Security: A mounting plate ensures that the winch is firmly attached to the vehicle, providing the necessary stability and security during use.

- Compatibility: Winch mounting plates are designed to fit specific winch models and vehicle types, ensuring proper alignment and function.

- Ease of Installation: Using a mounting plate simplifies the installation process, as it comes with pre-drilled holes and necessary hardware, making it easier to attach the winch to your vehicle.

- Safety: A properly mounted winch reduces the risk of accidents and damage to your vehicle by ensuring that the winch operates correctly and remains secure during heavy pulls.

Do All Bumbers Require a Winch Plate?

Not all bumpers require a winch plate, and here’s why:

Standard Bumpers:

Designed for aesthetics and minor impacts; made from light materials like plastic or thin metal. Can’t handle winching forces without a winch plate, leading to potential damage.

Off-Road Bumpers:

Built from heavy-duty materials like steel or reinforced aluminum. Often have reinforced mounting points but still benefit from a winch plate for extra security and stability.

Also Check

Conclusion

Winch plates are essential for various lifting and pulling tasks across industries like construction, automotive, and marine.

They provide a secure base for winches, enabling efficient and safe operation. Understanding their components, mechanical principles, and variations helps in selecting the right winch plate for specific needs.

Proper installation, maintenance, and safety practices ensure optimal performance and longevity. Always consult professionals and follow guidelines to maximize safety and efficiency.