Wiring a winch remote control involves connecting the control box to the winch motor using color-coded wires and securing a power source, usually from the vehicle’s battery. This guide explains the wiring process in detail, including what tools you need, how to test the system, and common troubleshooting issues.

Whether you’re working on a wired or wireless remote, understanding the wiring process is essential for reliable performance.

In this article, we’ll guide you step-by-step through the process, covering everything from gathering the necessary tools to preparing a wiring harness, connecting wires to terminals, grounding, and testing. With these tips, you can ensure a secure and functional setup.

Quick Answer

To wire a winch remote control, disconnect the battery for safety, connect the positive and negative wires to the winch motor and grounding point, and attach the control wires to the winch control box. Ensure proper insulation and test the remote functions after reconnecting the battery. This step-by-step guide explains the process in detail below.

Tools and Materials Required

Before we dive into the wiring process, make sure you have the following tools and materials on hand:

Tools:

- Wire strippers for precise cutting

- electrical crimpers for secure connections

- insulated pliers for safe handling

- Electrical tape (optional)

Materials:

- Winch remote control unit

- Wiring harness (typically included with the winch or remote control)

- Connectors (butt connectors, crimp connectors, etc.)

- Heat shrink tubing (optional)

- Heat-resistant connectors for reliable winch motor connections.

It’s crucial to follow the manufacturer’s instructions for your specific winch and remote control model. Referencing the provided manuals ensures you have the necessary components and understand any specific requirements.

How to Prepare Wiring for Winch Remote Control Setup

Step 1: Disconnect the Battery

Safety is crucial when working with electrical systems, especially in automotive or heavy machinery settings.

Disconnecting the battery is the first step in any electrical installation to avoid shocks or sparks. Disconnecting the battery ensures safety by preventing short circuits during winch remote installation.

For this task, you typically locate the battery terminals and remove the negative terminal first. This disruption in the circuit minimizes the risk of completing an electrical circuit accidentally while working on the wiring.

Step 2: Identify the Wiring Harness and Connectors

A wiring harness is an organized set of wires, terminals, and connectors that run throughout the vehicle or machinery. The wiring harness serves as the communication link between the winch motor and remote control.

Ensure compatibility with your specific winch model. For installing a winch remote control, the harness will specifically facilitate connections from the remote to the winch itself.

- Locating the Harness: Begin by locating the wiring harness that was included with your remote control kit. This harness usually consists of several colored wires and ends with various connectors.

- Identifying Connectors and Terminals: Examine the connectors at the ends of the harness. These should match the input terminals on your winch and possibly the power terminals (battery). Properly matching the connectors ensures effective communication between the remote control and winch motor.

- Compatibility Check: Ensure that the harness fits properly with your winch model. Mismatches in connector types or sizes can lead to ineffective connections or damage to the electrical components.

Step 3: Strip the Wire Ends and Prepare for Connection

Once you have your harness ready and laid out, the next step involves preparing the wire ends for connection. This step is vital for a solid electrical connection.

- Stripping the Wires: Use wire strippers to remove approximately ¼ inch (6 mm) of insulation from the ends of each wire. This exposed area is where the metal wire is visible, which will be used to make electrical connections.

- Clean Stripping: Ensure that the stripping is clean and that no strands are damaged. Damaged or frayed wires can lead to poor connections and potential electrical hazards.

- Preparing for Secure Connection: Once stripped, the wires can be inserted into the terminal connectors or directly onto the terminal posts, depending on the design of your wiring setup. It’s essential to ensure that the bare wire does not touch any other wires or metal surfaces to avoid short circuits.

Connecting the Winch Remote Control

Connecting the winch remote control involves carefully linking the control unit to the winch and power source through proper wiring.

Step 1: Connect the Positive (+) Wire to the Winch Motor

This step is crucial as it establishes the power supply from the battery to the winch motor through the remote control.

- Locating the Positive Terminal: Identify the positive terminal on the winch motor. This terminal is typically marked with a plus (+) sign or might be color-coded in red.

- Attaching the Wire: Take the positive wire from the remote control kit (also usually red) and securely attach it to the positive terminal of the winch motor. Make sure the connection is tight and the wire is not loose, as a loose connection can lead to a drop in power efficiency and potential electrical hazards.

- Securing the Connection: Use a wrench or a suitable tool to tighten the terminal bolt, ensuring that the wire is firmly held in place and has good contact with the terminal.

Step 2: Connect the Negative (-) Wire to the Grounding Point

Establishing a ground connection is essential for completing the electrical circuit and for safety.

- Choosing a Grounding Point: Select a grounding point on your vehicle or machinery. This point should be a metal part of the frame or engine that is clean and free of paint or rust.

- Securing the Wire: Attach the negative wire (usually black) from the remote control kit to the grounding point. Ensure that it is as short as possible to minimize resistance and potential voltage drop.

- Bolting the Connection: Bolt down the connection if possible. A bolted connection is more secure and reliable than a simple wrap-around, especially in a vibrating environment like that of a winch.

Step 3: Connect the Control Wires

Control wires are what allow the remote to command the winch to wind in, wind out, or stop. Each control wire corresponds to functions like ‘winch in’ or ‘winch out.’ Use color-coded wires for easy identification and accurate connections.

- Identifying Control Wires: Identify the wires for different functions such as “in,” “out,” and “stop.” These wires are often color-coded or labeled for ease of identification.

- Connecting to Corresponding Terminals: Connect these wires to the corresponding terminals on the winch control box. Ensure each terminal is clearly labeled and refer to your winch’s manual for accurate connections.

- Testing Each Function: As you connect each wire, it’s a good practice to test each function to ensure the wire is properly connected and the function operates as expected.

Step 4: Secure the Connections

Once all wires are connected, securing them is vital to ensure they remain intact and functional over time.

- Using Connectors: Where applicable, use the provided electrical connectors to join wires to the terminals. These connectors ensure a more stable and secure connection than twisting wires together.

- Applying Heat Shrink Tubing: For an extra layer of security and to protect the connections from the elements, slide heat shrink tubing over the connections before heating it to a snug fit. This tubing provides insulation and helps prevent corrosion and wear due to moisture and dirt.

- Final Inspection: Conduct a final inspection to make sure all wires are properly routed away from any moving parts and heat sources, and that they are securely fastened to prevent chafing.

Testing and Troubleshooting Winch Remote Control Wiring

Step 1: Reconnect the battery

After ensuring all connections are properly made, reconnect the negative (-) battery terminal.

Step 2: Test the winch remote control operation

With the battery reconnected, test the winch remote control by pressing the respective buttons (in, out, stop, etc.). The winch should respond accordingly, confirming that the wiring is correct.

If the winch does not respond as expected, here are some troubleshooting tips:

- Double-check all wire connections for proper tightness and correct polarity.

- Verify that the control wires are connected to the correct terminals.

- Use a multimeter to test for proper voltage at the winch motor terminals.

- Consult the winch and remote control manuals for any specific troubleshooting guidelines.

Safety Precautions:

While wiring a winch remote control, it’s crucial to prioritize safety. Here are some important precautions to keep in mind:

- Always disconnect the battery before working on electrical components to prevent short circuits or electrical shocks.

- Ensure that the winch is rated for the intended load capacity and is properly anchored to a secure mounting point.

- Never operate the winch with people or objects in the potential path of the cable or load.

- Inspect the winch, cable, and all components regularly for signs of wear or damage.

- Consult the winch and vehicle manuals for specific safety guidelines and weight ratings.

FAQs

What gauge of wire should I use?

Select a wire gauge that can handle the current requirements of your winch without overheating or losing efficiency.

Do I need a fuse for the winch remote control?

Yes, installing a fuse in the power line to the winch can prevent potential electrical hazards and equipment damage.

How do I ensure compatibility between my winch and the remote control?

Check the manufacturer’s specifications for both the winch and the remote control to ensure compatibility. If unsure, consult with a professional or contact customer support.

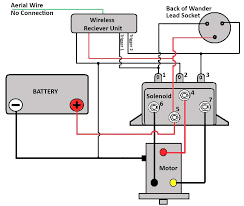

Can I install a wireless remote control on my existing winch?

Yes, most winches are compatible with wireless control modules. Simply connect the wireless receiver to the winch solenoid following the manufacturer’s wiring diagram.

How do I troubleshoot a winch remote that doesn’t work?

Verify all connections, test the voltage at the winch motor terminals using a multimeter, and ensure the remote control battery is charged.

What is the purpose of grounding in winch wiring?

Grounding completes the electrical circuit, ensures safety, and prevents damage to the winch motor by stabilizing the electrical current.

Do I need to use heat-resistant connectors for winch wiring?

Yes, heat-resistant connectors provide reliable connections, especially in high-current applications, and prevent melting or damage under heavy loads.

What tools are essential for winch remote control installation?

Essential tools include wire strippers, crimpers, pliers, and optionally, heat shrink tubing and electrical tape for insulation.

Can I connect multiple remotes to a single winch?

Some winches allow the use of both wired and wireless remotes simultaneously. Check your winch’s manual for compatibility.

How do I test a newly installed winch remote control?

Reconnect the battery and press the “in” and “out” buttons on the remote to ensure the winch responds correctly. Verify all wiring connections if it doesn’t operate as expected.

Is a wiring harness required for every winch installation?

Most winch remote kits include a wiring harness. If not, a compatible harness must be used to ensure proper connections and functionality.

Conclusion

Properly wiring your winch remote control is crucial for safe and efficient winch operation. By following this detailed guide, you can ensure that your remote control is correctly installed and fully functional.

Always prioritize safety and consult your equipment manuals for any specific instructions or troubleshooting needs. With these steps, you’re set for a successful and safe winching experience.