The required thickness varies based on the application:

For lightweight applications, such as off-road or recovery uses, steel plates should be 5 mm to 10 mm thick, while aluminum plates should be 8 mm to 12 mm thick.

For heavy-duty applications, like industrial or construction settings, steel plates should be 12 mm to 20 mm thick, and aluminum plates should be 15 mm to 25 mm thick.

In this comprehensive guide, we’ll explore the factors that determine the appropriate winch plate thickness and provide practical guidelines to help you make an informed decision.

Factors Affecting Winch Plate Thickness

Several factors influence the required thickness of a winch plate:

Load Capacity:

The winch’s rated capacity, typically measured in pounds or tons, is one of the most significant factors influencing the required winch plate thickness.

A higher load capacity translates to greater forces exerted on the plate during winching operations. As a general rule, the thicker the winch plate, the better it can withstand the stresses and prevent deformation or failure.

Here are some guidelines for matching plate thickness to winch capacity:

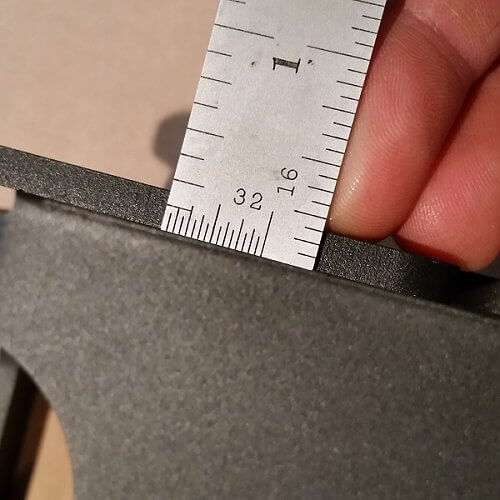

- For light-duty winches (up to 6,000 lbs. capacity): 1/4 inch (6.35 mm) minimum plate thickness

- For medium-duty winches (6,000 – 12,000 lbs. capacity): 3/8 inch (9.53 mm) minimum plate thickness

- For heavy-duty winches (12,000 – 18,000 lbs. capacity): 1/2 inch (12.7 mm) minimum plate thickness

- For extreme-duty winches (above 18,000 lbs. capacity): 3/4 inch (19.05 mm) or thicker, depending on the specific application

Mounting Surface

The strength and rigidity of the mounting surface play a crucial role in determining the required winch plate thickness.

If the mounting surface is sturdy and rigid, such as a vehicle’s frame or a heavy-duty trailer, a thinner plate may suffice.

However, if the mounting surface is less rigid or flexible, a thicker plate is necessary to compensate for the potential flexing or movement of the mounting surface during winching operations.

Material Strength

The strength of the material used for the winch plate is another vital factor. Different materials offer varying levels of strength, weight, and resistance to environmental factors.

- Steel: Steel is a common choice due to its high strength and durability. However, it is also heavier and more prone to corrosion compared to other materials. There are different types of steel, including mild steel and high-strength low-alloy (HSLA) steel, each with specific properties.

- Aluminum Alloys: Aluminum alloys, such as 6061 and 7075, are lighter than steel and offer good corrosion resistance. However, they may not be as strong as steel, requiring a thicker plate to achieve the same load-bearing capacity.

Application

The intended use of the winch plate also affects the required thickness. Different applications have varying demands:

- Off-Roading: Off-road applications often involve uneven terrain and sudden loads, requiring a robust winch plate that can handle such conditions. Typically, off-road winch plates can be slightly thinner due to the intermittent nature of the loads.

- Vehicle Recovery: Similar to off-roading, vehicle recovery involves pulling vehicles from difficult situations. The winch plate must withstand high loads and provide reliable performance, requiring adequate thickness.

- Industrial Purposes: Industrial applications, such as construction or heavy machinery operations, involve constant and heavy loads. These situations demand a thicker and stronger winch plate to ensure safety and durability.

Calculating Winch Plate Thickness

While general guidelines are helpful, it’s always recommended to consult with professionals or manufacturers for specific calculations based on your winch’s rated capacity, mounting surface, and intended use.

However, here’s a basic formula that can provide a rough estimate of the required winch plate thickness:

Plate Thickness (inches) = (Winch Capacity (lbs) × Safety Factor) / (Plate Width (inches) × Plate Length (inches) × Yield Strength (psi))

- Winch Capacity: The maximum rated pulling capacity of your winch

- Safety Factor: A multiplier (typically 2 or higher) to account for dynamic loads and ensure a safety margin

- Plate Width and Plate Length: The dimensions of your winch plate

- Yield Strength: The material’s yield strength, which varies depending on the chosen material (e.g., steel, aluminum)

For example, if you have a 10,000 lbs. winch, a safety factor of 2, a plate size of 12 inches by 12 inches, and you’re using mild steel with a yield strength of 36,000 psi, the calculation would be:

Plate Thickness = (10,000 lbs × 2) / (12 inches × 12 inches × 36,000 psi) = 0.463 inches (rounded up to 1/2 inch)

It’s important to note that this is a simplified calculation, and it’s always recommended to consult with professionals or manufacturers for more accurate calculations based on your specific application and conditions.

Installation and Mounting Considerations

Proper installation is key to maximizing the effectiveness of your winch plate:

- Mounting Techniques:

Whether you choose bolting or welding, ensure the method provides a secure fit. - Load Distribution:

Reinforce the plate to distribute the load evenly and avoid stress concentrations. - Alignment and Positioning:

Ensure the winch plate is aligned correctly for optimal performance and to prevent any twisting or bending.

Also check: How to Install a Winch Mounting Plate Easily

FAQ

Can I use a thicker winch plate than recommended?

Using a thicker winch plate than recommended is generally acceptable, as it will provide extra strength and stability. However, ensure that the added thickness does not interfere with the winch’s operation or clearance.

Can I use a thinner winch plate to save weight?

While using a thinner winch plate may save some weight, it’s not recommended as it can compromise the strength and safety of the winch setup. Always prioritize safety over weight savings when it comes to winch plates.

Do I need a different winch plate thickness for synthetic ropes or cables?

The winch plate thickness is primarily determined by the winch’s rated capacity and the mounting surface, not the type of rope or cable used. However, follow the manufacturer’s recommendations for any specific requirements related to synthetic ropes or cables.

Can I use a winch plate made from a different material than recommended?

While it’s possible to use winch plates made from different materials, it’s essential to consider the material’s strength and ensure that the plate thickness is adjusted accordingly. Consult with professionals or manufacturers for guidance on using alternative materials.

Conclusion

Selecting the appropriate winch plate thickness is crucial for safe winching operations.

Always consider the load capacity, material strength, and specific application when choosing a winch plate. Safety should be your top priority, so adhere to manufacturer guidelines and consult professionals if you have any doubts.