Can you power a winch with your 7-way trailer connector? No, the 7-way connector isn’t designed for the high power demands of a winch. While it might seem convenient to use the existing connection, it can be dangerous and damaging to both your vehicle and equipment.

Let’s dive deeper into why using the 7-way connector for a winch is a bad idea and explore safer alternatives to get you out of sticky situations, trailer or not.

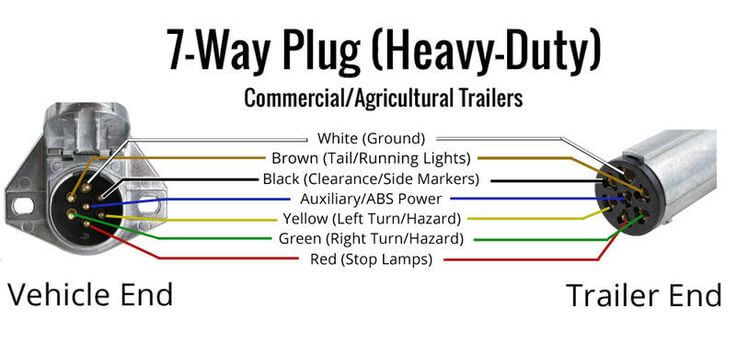

Understanding the 7-Way Trailer Connector

Understanding the 7-Way Trailer Connector in detail involves delving into its design, functionality, and limitations, particularly in relation to powering a winch.

Design and Functionality

The 7-way trailer connector, often found on RVs, larger trailers, and some towing vehicles, is ingeniously designed to serve multiple electrical needs simultaneously. Its configuration typically includes seven pins, each assigned to a specific function:

- Tail Lights: This pin powers the running lights on the trailer’s rear and sides, ensuring visibility in low-light conditions.

- Left and Right Turn Signals: Separate pins for left and right turn signals ensure directional indicators work correctly, which is crucial for safe towing.

- Brake Lights: This connection activates the trailer’s brake lights, signaling to drivers behind when the towing vehicle is slowing down or stopping.

- Reverse Lights: Engaged when the towing vehicle is in reverse, these lights help in backing up the trailer safely.

- Electric Brakes: If the trailer is equipped with electric brakes, this pin controls them, allowing synchronized braking with the towing vehicle.

- 12V Power Supply: This line provides a continuous power supply from the towing vehicle’s battery, which can be used for various purposes, including charging the trailer’s battery.

- Ground Connection: Essential for completing the electrical circuit and ensuring safe operation.

Power Output and Limitations

While the 7-way connector is versatile, its power output, especially the 12V line, is designed for low-draw applications.

This line is typically used for maintaining battery charge, powering interior lights, or running small appliances within the trailer. The key aspect to consider is the amperage capacity of this 12V supply line.

When it comes to winches, the power demand significantly exceeds what most 7-way connectors are designed to handle. A standard winch can draw substantial amperage, particularly under load when pulling heavy items. This high demand for power can pose several risks if attempted through a 7-way connector:

- Overheating: The connector and the wiring may not be designed to handle the high current drawn by a winch, leading to overheating.

- Wire Gauge Limitation: The gauge of the wire used in standard 7-way connectors might not be sufficient for the high current, increasing the risk of wire melting or fire.

- Voltage Drop: Under high load, there can be a significant voltage drop, which may render the winch less effective or even damage it.

- Blown Fuses or Tripped Breakers: The vehicle’s electrical system might not be equipped to handle such a load, leading to blown fuses or tripped circuit breakers.

Winches and Power Requirements

Winches are fundamental tools in various applications, from off-road adventures to industrial operations. Their primary function is to pull heavy loads, which inherently demands a significant amount of power. Understanding the power requirements of winches is crucial, especially when considering the compatibility of power sources like a 7-way trailer connector.

The Nature of Winches

A winch is essentially a mechanical device used for winding up or winding out a cable or a rope to pull or lift heavy objects. They are commonly found on the front of off-road vehicles, trailers, and in industrial settings. The core components of a winch include a motor, a drum for winding the cable, gears, and the cable itself.

Power Requirements of Winches

The power requirements of winches vary greatly and are influenced by several factors:

- Load Capacity: This is perhaps the most significant factor. The heavier the load that needs to be pulled, the more power the winch requires. Winches are rated by their maximum load capacity, which can range from a few hundred pounds to several tons.

- Operation Duration: The length of time the winch is operated also impacts its power usage. Continuous or prolonged use, especially under maximum load, will require more power and can lead to significant heat buildup in the motor.

- Motor Type: Winches are typically powered by electric or hydraulic motors. Electric winches are more common and are powered by the vehicle’s battery or an external power source. The power draw of these motors varies based on their size and efficiency.

- Amperage Draw: This is where the real concern lies. A standard electric winch can draw a substantial amount of current, particularly when under load. For instance, a winch rated for 9,000 pounds might draw between 200 to 400 amps when under full load. This amperage draw is a critical consideration when connecting a winch to a power source.

Compatibility with 7-Way Trailer Connector

Considering the high amperage requirements of winches, the modest power output of a 7-way trailer connector is generally not sufficient. These connectors are designed to handle the electrical needs of trailer lights and brakes, which are significantly lower in power demand compared to winches.

- Power Output Limitation: The 12V power line in a 7-way connector is not designed to handle high currents. It is typically used for low-power applications like charging a battery or powering lights.

- Risk of Overloading: Attempting to power a winch through a 7-way connector can lead to overloading the connector and the vehicle’s electrical system. This can result in overheating, wire damage, or even electrical fires.

- Voltage Drop and Inefficiency: Even if the connector and wiring could handle the current, there’s a risk of significant voltage drop. This can render the winch inefficient or cause it to fail, especially during critical operations.

Can a 7-Way Trailer Connector Power a Winch?

When considering the feasibility of using a 7-way trailer connector to power a winch, it’s crucial to delve into the technical aspects of both the connector and the winch’s power requirements. This understanding is key to assessing whether such a setup is practical or even safe.

Understanding the 7-Way Trailer Connector’s Capabilities

The 7-way trailer connector, commonly found on RVs and trailers, is designed to handle various electrical needs of a trailer. This includes:

- Lighting: Tail lights, brake lights, and turn signals.

- Auxiliary Power: A 12V supply line for auxiliary applications.

- Brake Control: For trailers with electric brakes.

The 12V power line in the 7-way connector is specifically designed for low-draw applications. This might include charging a small battery, powering interior lights, or running other low-power accessories. The key here is “low-draw” – these applications typically require a relatively small amount of current.

Winches: High-Demand Power Users

Winches, particularly those used for heavy-duty pulling, are high-demand power users. They require a substantial amount of electrical power, especially under load. Here’s why:

- High Amperage Draw: When under load, winches can draw a significant amount of current. For instance, a winch rated for heavy-duty pulling might require hundreds of amps to operate effectively. This is far beyond what the 12V line on a 7-way connector is designed to handle.

- Sustained Power Needs: Unlike lighting or brake controls, which require power intermittently, winches may need sustained power over a longer period, especially during continuous pulling tasks.

The Risks of Using a 7-Way Connector for Winches

Attempting to power a winch using a 7-way trailer connector involves several risks:

- Overheating: The high current draw of the winch can cause the wiring of the 7-way connector to overheat. This is particularly concerning if the wiring is not rated for such high amperage, which is often the case.

- Damage to Vehicle’s Electrical System: Overloading the 7-way connector can lead to broader issues within the vehicle’s electrical system. This includes blown fuses, damaged wiring, and in severe cases, it can cause electrical fires.

- Voltage Drop: Even if the connector and wiring do not overheat, there’s a risk of significant voltage drop under the high load of a winch. This can lead to inefficient winch operation or even failure, particularly in critical situations where reliable winch operation is essential.

- Potential Winch Damage: Inadequate power supply can also damage the winch itself. Winches are designed to operate within certain electrical parameters, and deviating from these can lead to malfunction or permanent damage.

Case Studies: Learning from Real-World Applications

Analyzing specific case studies provides deeper insights into the feasibility of this setup:

- Case Study 1: Light-Duty Winch on a Small Trailer: In one instance, a user successfully used a 7-way connector to power a light-duty winch for occasional use. The winch’s amperage draw was within the capacity of the connector, and the operation duration was short, minimizing the risk of overheating.

- Case Study 2: Heavy-Duty Winch Failure: Another case involved an attempt to power a heavy-duty winch for a large boat. The high amperage draw of the winch led to an overheated connector and a blown fuse in the towing vehicle, ultimately requiring costly repairs.

- Case Study 3: Hybrid Power Solution: A more complex case involved a user who set up a secondary battery system charged through the 7-way connector. This battery then provided power to the winch. This setup offered a balance, providing sufficient power for the winch while protecting the vehicle’s electrical system from overload.

Key Takeaways

From these varied experiences, several key takeaways emerge:

- Understand the Limitations: It’s crucial to understand both the power needs of the winch and the capacity of the 7-way connector. Overestimating the connector’s capacity can lead to failure and damage.

- Safety First: Even if a setup seems to work initially, continuous monitoring for signs of overheating or electrical issues is essential to ensure safety.

- Seek Professional Advice: For those considering a non-standard setup, consulting with a professional can provide guidance and help mitigate risks.

- Be Prepared for Trial and Error: Even with careful planning, using a 7-way connector for winch power can be a trial-and-error process, and being prepared for potential issues is important.

Alternative Power Solutions for Winches

When the standard power supply from a 7-way trailer connector is insufficient for a winch, exploring alternative power solutions becomes essential. These alternatives are designed to meet the high power demands of winches without compromising the safety and integrity of the vehicle’s electrical system. Let’s delve into two popular alternatives: a separate battery setup and upgrading to a more robust connector.

Separate Battery Setup

A separate battery setup involves using an independent battery solely to power the winch. This system is particularly advantageous in scenarios where the winch requires a power supply that exceeds what the vehicle’s electrical system can safely provide.

Pros:

- Dedicated Power Source: The winch operates on its own power supply, ensuring that it receives the necessary power without affecting the vehicle’s electrical system.

- Flexibility in Usage: This setup is ideal for situations where the winch needs to be used at a distance from the vehicle or in a stationary setting.

- Reduced Risk of Overloading: By isolating the winch’s power supply, there’s a significantly lower risk of overloading the vehicle’s electrical system, thus preventing potential damage.

Cons:

- Additional Cost: Setting up a separate battery system incurs extra costs, including the battery itself, housing, wiring, and potentially a charging system.

- Maintenance Requirements: The battery requires regular maintenance, including charging and checks to ensure it’s in good working condition.

- Added Weight and Space: The battery adds extra weight to the setup and requires space, which might be a consideration for smaller vehicles or trailers.

Upgrading to a More Robust Connector

Upgrading to a connector that can handle higher amperage is another viable solution. This involves replacing the standard 7-way connector with a more heavy-duty connector designed to handle higher current loads.

Pros:

- Increased Power Capacity: A robust connector can safely transmit higher currents, making it suitable for more powerful winches.

- Direct Power from Vehicle: This setup allows the winch to draw power directly from the vehicle’s battery, ensuring efficient operation without the need for additional batteries.

- Simplified Setup: Upgrading the connector is generally a simpler process than setting up a separate battery system.

Cons:

- Vehicle Compatibility: Not all vehicles may be compatible with higher amperage connectors, and modifications might be required.

- Potential Strain on Vehicle’s Electrical System: Even with a robust connector, there’s a risk of straining the vehicle’s electrical system, especially if the winch is used extensively or under heavy load.

- Installation Complexity: Upgrading the connector might require professional installation, especially if it involves modifications to the vehicle’s existing electrical system.

Safety Considerations and Best Practices

When it comes to operating winches, particularly in conjunction with electrical systems like those in vehicles and trailers, safety considerations are paramount. The inherent risks associated with electrical systems, such as short circuits, overheating, and fire hazards, necessitate a proactive approach to safety. Here’s a detailed look at the key safety considerations and best practices to follow:.

Understanding the Limitations of Your Equipment

- Know Your Winch’s Specifications: Be fully aware of your winch’s power requirements, including its maximum amperage draw and voltage. This knowledge is crucial in selecting the appropriate power source and avoiding overloading electrical systems.

- Assess the Electrical System’s Capacity: Understand the limitations of your vehicle or trailer’s electrical system. This includes knowing the maximum current your 7-way connector or any alternative connector can handle.

- Check Compatibility: Ensure that all components in your setup, including the winch, connectors, and power source, are compatible with each other. Mismatched components can lead to electrical failures.

Prioritizing Electrical Safety

- Use Properly Rated Cables and Connectors: Always use cables and connectors that are rated for the current your winch will draw. Underrated cables can overheat, leading to insulation melt, short circuits, or fires.

- Regular Inspections: Regularly inspect all electrical connections, cables, and connectors for signs of wear, damage, or corrosion. Outdoor conditions can accelerate wear, so frequent checks are necessary.

- Secure Connections: Ensure all electrical connections are secure and properly insulated. Loose connections can lead to arcing and overheating.

Best Practices in Winch Operation

- Operate Within Rated Capacities: Never exceed the rated capacity of your winch. Overloading the winch can lead to mechanical failure and create dangerous situations.

- Monitor for Overheating: During operation, periodically check the winch and its power source for signs of overheating. If any component becomes too hot to touch, stop operation immediately to allow it to cool down.

- Use Circuit Protection: Employ appropriate circuit protection, such as fuses or circuit breakers, to prevent overcurrent situations. This is especially important if you’re drawing power directly from a vehicle’s battery.

- Be Prepared for Emergencies: Have a fire extinguisher rated for electrical fires readily available whenever operating the winch.

- Educate Yourself and Others: Understand the basics of electrical safety and ensure anyone else involved in the winch operation is also aware of these safety practices.

- Follow Manufacturer’s Guidelines: Always adhere to the manufacturer’s instructions for both the winch and any electrical components you use. These guidelines are designed to ensure safe operation.

Conclusion

While it’s technically possible to power a winch using a 7-way trailer connector, it’s not always advisable. The risk of overloading and potential damage to your vehicle’s electrical system is a real concern. For those who choose to explore this option, proceed with caution, armed with the right knowledge and safety measures.