Purchasing a pre-made winch plate is an option, building your own can save you money and give you the satisfaction of a custom-made product tailored to your vehicle’s specific needs.

In this article, let’s learn how you can build your own winch plate and enjoy these benefits.

Quick Answer

How to Build a Winch Plate

To build a winch plate, start by measuring and cutting steel or aluminum to fit your vehicle. Drill mounting holes based on your winch’s specifications, weld the components securely, and grind the edges for safety. Test-fit the plate on your vehicle to ensure proper alignment before final installation. Optional additions like powder coating or D-ring mounts can enhance durability and utility.

Choosing the Right Materials

When it comes to building a winch plate, choosing the right materials is crucial. The most common options are steel and aluminum.

Steel

Pros:

Durability: Steel is incredibly strong and can withstand heavy use.

Cost: Generally, steel is less expensive than aluminum.

Cons:

Weight: Steel is heavy, which can add significant weight to your vehicle.

Corrosion: Steel can rust if not properly treated or maintained.

Aluminum

Pros:

Weight: Aluminum is much lighter than steel, which can improve your vehicle’s performance.

Corrosion Resistance: Aluminum doesn’t rust, making it a great option for wet and muddy conditions.

Cons:

Cost: Aluminum is usually more expensive than steel.

Strength: While strong, aluminum is not as durable as steel and can be more prone to bending under extreme stress.

My Recommendation:

If durability and cost are your main concerns, steel is the way to go.

However, if you’re looking to reduce weight and don’t mind spending a bit more, aluminum is an excellent choice.

Tools and Equipment Needed

To build a winch plate, you’ll need a variety of tools. Using essential tools like a plasma cutter for precision cuts and a bending brake to shape metal can make the process of building a winch plate more efficient and safer. Here are the essentials:

Welder: For joining metal pieces together.

Grinder: To smooth edges and remove any sharp burrs.

Drill: For creating holes for bolts and mounting points.

Measuring Tape: Accuracy is key, so precise measurements are a must.

Safety Gear: Gloves, safety glasses, and hearing protection are crucial to stay safe.

In some cases, you might need specialized tools such as a plasma cutter for more precise cuts or a bending brake to shape metal.

Other helpful tools include clamps for stability during welding, a level for alignment, and a wire brush to clean metal surfaces before welding.

Always prioritize safety when working with power tools. Wear appropriate safety gear and work in a well-ventilated area to avoid inhaling fumes.

Step-by-Step Instructions for Building Your Winch Plate

Step 1: Measure and Cut the Material

Measuring:

First, you need to decide on the size of your winch plate. This will depend on the winch you plan to use and the vehicle it will be mounted on.

Use a tape measure to get the exact dimensions. It’s a good idea to measure twice to avoid mistakes. Mark the measurements on your material with a marker.

For accurate dimensions, use a template or CAD design specific to your winch model and vehicle type.

Ensure the lines are straight and clear, as accuracy is critical for a perfect fit.

Cutting:

Once you’ve marked your material, it’s time to cut. If you’re using steel or aluminum, a grinder or plasma cutter will work best.

Ensure the material thickness matches the winch’s weight capacity—1/4 inch for lighter loads, or up to 3/8 inch for heavier-duty applications.

A grinder with a cutting disc is more common and should suffice for most DIY projects. If you have access to a plasma cutter, it can make more precise cuts, especially for intricate shapes.

- Using a Grinder:

Wear safety goggles and gloves. Secure the material firmly, so it doesn’t move during cutting. Follow your marked lines slowly and steadily to ensure a clean cut. - Using a Plasma Cutter: This tool is quicker and more precise. Follow the same safety precautions, ensuring your lines are accurate.

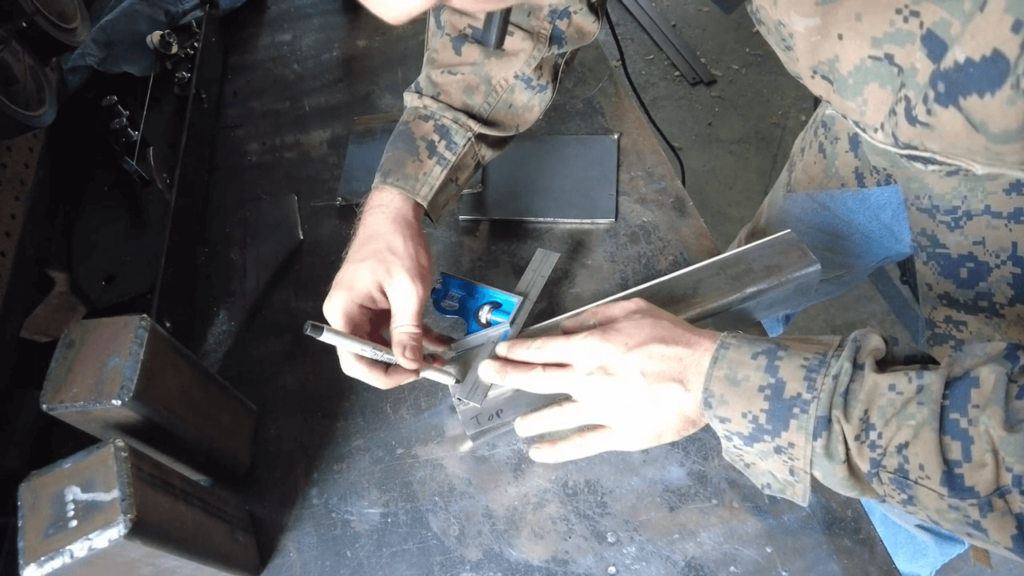

Step 2: Drill Mounting Holes

Marking the Holes:

With your material cut to size, the next step is to mark where your mounting holes will go. These holes are crucial for securing the winch plate to your vehicle and for attaching the winch itself.

Refer to your winch’s manual for the specific hole pattern and spacing required. Use a ruler and marker to mark these spots accurately on your plate.

Drilling:

Choose a drill bit that matches the size of the bolts you will be using. Drill holes slightly larger than the bolt diameter to allow for flexibility during installation while ensuring a secure fit.

A pilot hole can help maintain drill precision, especially when working with thicker steel plates. Typically, you’ll need a bit that’s slightly larger than the bolt diameter to allow for a snug fit.

Clamp the plate securely to a workbench to prevent it from moving. A pilot hole can help maintain drill precision, especially when working with thicker steel plates.

Drill each marked spot carefully, ensuring the drill is perpendicular to the plate for straight holes.

Go slowly to avoid overheating the drill bit and creating uneven holes.

Step 3: Weld the Components

Preparation:

If your design requires multiple pieces to be joined, welding is the way to go. Before you start welding, make sure all the pieces fit together as planned.

Clean the edges that will be welded to remove any dirt, oil, or rust, as these can weaken the weld.

Welding:

Set up your welder according to the type of material you’re using (steel or aluminum). Wear appropriate safety gear, including a welding helmet, gloves, and protective clothing.

When welding steel, ensure a continuous bead to prevent stress points; for aluminum, consider using TIG welding for cleaner joints.

Tack weld the pieces in place first to hold them together. This involves making small welds at several points along the joints.

Once the pieces are securely tacked, weld along the entire joint in a steady, continuous motion. Ensure your welds are strong and even, as the strength of your winch plate depends on it.

Step 4: Grind and Smooth Edges

Grinding:

After welding, you’ll likely have some rough edges and weld splatter. Use a grinder with a flap disc to smooth out these areas.

Polish edges with a fine-grit grinder disc for a smooth finish, especially at mounting points, to avoid scratching your vehicle.

Grinding not only makes your winch plate look more professional but also ensures there are no sharp edges that could cause injury.

Smoothing:

Go over all the edges and welded seams, making sure everything is smooth to the touch. Pay extra attention to areas where you’ll be handling the plate or where it will come into contact with your vehicle.

A smooth finish will also make it easier to apply any protective coatings or paint later on.

Step 5: Test Fit and Final Adjustments

Test Fitting:

Before you call the project complete, it’s crucial to test fit the winch plate on your vehicle.

This step ensures that all your measurements and cuts were accurate and that the plate fits perfectly with your winch and vehicle mounting points.

Align the winch plate with factory mounting points and verify that there is no obstruction for winch cable operation or fairlead placement.

Mounting:

Temporarily attach the winch plate to your vehicle using the bolts. Check for any misalignment or gaps.

Adjustments:

If you find any issues, mark the areas that need adjustment.

You may need to drill additional holes, grind certain areas, or make slight bends.

Final Adjustments:

After test fitting, make the necessary adjustments to ensure everything lines up perfectly. Double-check the fit of the winch and make sure all bolts go through the mounting holes smoothly.

Once satisfied, remove the plate and prepare it for any finishing touches, such as painting or coating.

Also check: Best Winch Mounting Plate

Customization and Accessories

One of the fun parts of building your own winch plate is customizing it to fit your style and needs. Here are some ideas:

Powder Coating:

This process involves applying a dry powder to the surface of your winch plate, which is then heated to create a durable and attractive finish.

Powder coating not only looks great but also helps prevent rust and corrosion, extending the life of your winch plate. Consider adding a durable powder coating to protect the winch plate from corrosion and enhance its appearance.

Additional Features:

Think about adding extra mounting points or reinforcing certain areas. Extra mounting points can be used for attaching other off-road accessories like lights or D-rings.

Include D-ring mounts or additional holes for off-road accessories like light bars or recovery points. Reinforcing the plate in key areas can provide extra strength, ensuring it can handle heavy loads and harsh conditions.

Compatible Accessories

Enhancing your winch plate with the right accessories can improve its functionality and your overall off-road experience:

Fairlead:

This is an essential component that guides the winch cable and prevents it from fraying. There are two main types of fairleads,

roller fairleads, which have multiple rollers to guide the cable,

hawse fairleads, which are simpler and used with synthetic ropes.

Synthetic Rope:

Compared to traditional steel cables, synthetic ropes are lighter, safer, and easier to handle. They don’t develop sharp burrs like steel cables, reducing the risk of injury.

They also float on water, making them easier to use in wet conditions.

D-Rings:

Adding D-rings to your winch plate provides additional recovery points. These sturdy rings are essential for attaching tow straps and other recovery gear, making it easier to get out of tough spots when off-roading.

Customizing your winch plate and adding the right accessories not only enhances its appearance but also boosts its functionality, making your off-road adventures safer and more enjoyable.

FAQs

How thick should a winch plate be?

The ideal thickness for a winch plate depends on the weight of the winch and the vehicle. Generally, 1/4 inch is sufficient for most applications, but 3/8 inch or more is recommended for heavy-duty use.

Can I build a winch plate without welding?

Yes, you can build a winch plate using bolts and pre-drilled plates, but welding ensures a stronger and more reliable connection.

What material is best for a winch plate?

Steel offers durability and cost-effectiveness, while aluminum provides corrosion resistance and lighter weight for improved vehicle performance.

What tools do I need to build a winch plate?

Essential tools include a welder, grinder, drill, measuring tape, and safety gear. Additional tools like a plasma cutter, clamps, and wire brush can make the process more efficient.

How do I ensure my winch plate fits my vehicle?

Measure the mounting points on your vehicle and the winch’s bolt pattern. Test fit the plate before finalizing to ensure proper alignment and compatibility.

Can I customize my winch plate?

Absolutely! You can add powder coating for corrosion resistance, extra mounting points for accessories like light bars, or reinforced areas for added durability.

How much weight can a DIY winch plate handle?

The weight capacity of a DIY winch plate depends on the materials and thickness used. A 1/4-inch steel plate can generally handle standard winches up to 9,000 lbs, while 3/8-inch plates can support heavier loads.

Is building a winch plate cost-effective?

Yes, building a winch plate is often cheaper than buying a pre-made one. You can customize it to your needs and save on costs, especially if you already have the tools.

Conclusion

Building a winch plate is a project that not only enhances your off-road capabilities but also gives you a sense of accomplishment.

By choosing the right materials, using the proper tools, and following detailed instructions, you can create a winch plate that is both functional and customized to your needs.

Remember, safety first, and enjoy the process of building and using your new winch plate. Feel free to share your experiences or ask any questions!