Winch straps are essential tools used in off-road recovery, flatbed transport, and cargo control.

Typically made from heavy-duty polyester, they attach to winches to help pull, anchor, or secure vehicles and equipment. In this expert guide, we explain exactly what a winch strap is, how to use one properly, and what to consider when choosing the right strap for your needs.

Quick Answer

What is a Winch Strap?

A winch strap is a strong, heavy-duty strap designed to tow or recover vehicles and secure cargo using a winch. Made from materials like polyester, nylon, or Kevlar, winch straps provide durability, flexibility, and strength. They are essential tools for vehicle recovery, towing operations, and cargo control due to their ability to distribute loads evenly and maintain stability during pulling tasks.

What are Winch Straps?

Winch straps, sometimes referred to as flatbed winch straps or vehicle recovery straps, are heavy-duty straps used in conjunction with a winch to tow or recover vehicles and other objects.

Unlike other towing accessories, such as chains or cables, winch straps are made from flexible, lightweight materials that provide superior strength and durability.

This makes them ideal for a wide range of towing and recovery applications.

How Winch Straps Work

Winch straps are an essential component in the operation of a winch, which is a mechanical device used for pulling or lifting heavy objects.

The winch strap acts as the connecting link between the winch and the load, allowing for safe towing, cargo securing, and heavy-duty recovery by enabling the winch to apply the necessary force to move the object.

The process of how winch straps work can be broken down into several steps:

- Attachment: The winch strap is first attached to the object being pulled or lifted. This is typically done using a hook or a shackle at one end of the strap, which is secured to a designated point on the object. The other end of the strap is then attached to the winch itself, usually through a slot or opening in the winch drum. Check how to attach hook to winch strap.

- Winding: Once the winch strap is attached to both the object and the winch, the winch begins to wind the strap around its drum. The drum is a cylindrical component of the winch that rotates, powered either by an electric motor, hydraulic system, or manual operation, depending on the type of winch being used.

- Tension generation: As the winch drum rotates, it winds the strap around itself, gradually taking up the slack in the strap. This action creates tension in the strap, which in turn generates a pulling force on the object. The more the strap is wound around the drum, the greater the tension and pulling force become.

- Pulling: As the tension in the strap increases, it begins to pull the object towards the winch. The force applied by the winch is transmitted through the strap to the object, causing it to move in the direction of the winch. The speed and power of the pull depend on the winch’s specifications and the load being pulled.

- Load distribution: One of the key benefits of using a winch strap is its ability to distribute the load evenly across the surface of the object being pulled. The strap’s flexibility allows it to conform to the shape of the object, ensuring that the pulling force is applied uniformly. This even distribution of load helps to prevent damage to the object and ensures stability during the pulling operation.

- Stability: In addition to distributing the load evenly, the winch strap also helps to provide stability to the object being pulled. As the strap is being wound around the winch drum, it creates a stable connection between the object and the winch. This stability is essential for maintaining control over the object during the pulling process and preventing it from shifting or tipping.

Throughout the entire process, the winch strap plays a crucial role in transmitting the pulling force from the winch to the object.

The strap’s strength, durability, and flexibility are essential factors in ensuring a safe and successful pulling or lifting operation.

It is important to note that winch straps have specific load capacities and working load limits, which should never be exceeded.

Overloading a winch strap can cause it to fail, potentially leading to accidents, injuries, or damage to the object being pulled.

Always select a winch strap with a load capacity appropriate for the task at hand, and follow manufacturer guidelines and safety precautions when using winch straps.

Applications of Winch Straps

Winch straps are versatile tools that can be used in a wide range of applications, including:

- Vehicle recovery and towing: Winch straps are commonly used to recover stuck or disabled vehicles, as well as for towing purposes.

- Lifting and pulling heavy objects: In industrial and construction settings, winch straps are often used to lift and move heavy equipment, materials, and debris.

- Securing cargo during transportation: Winch straps can be used to secure cargo on trucks, trailers, and other vehicles, preventing shifting and damage during transit.

Benefits of Using Winch Straps

Using winch straps provides benefits like enhanced load security, even load distribution, and improved towing safety, making them a reliable choice for various pulling and lifting tasks:

- Enhanced safety: Winch straps are designed to distribute load evenly and maintain stability, reducing the risk of accidents and injuries.

- High load capacity and strength: High-quality winch straps can handle substantial loads, making them suitable for a wide range of heavy-duty applications.

- Versatility: Winch straps can be used in various settings and for different purposes, making them a valuable tool for many industries and situations.

- Durability and long-lasting performance: When properly maintained and used within their load limits, winch straps can provide reliable service for an extended period.

Top Materials for Winch Straps

Winch straps are typically made from one of three main materials:

1. Polyester

Polyester is a synthetic polymer known for its excellent strength-to-weight ratio.

This means that polyester winch straps can provide high breaking strength and load capacity while remaining relatively lightweight, making them easier to handle and store.

Polyester straps are also resistant to UV damage, which is a significant advantage when using them in outdoor environments.

Prolonged exposure to sunlight can degrade and weaken certain materials, but polyester’s UV resistance preserves its strength and integrity.

Another benefit of polyester winch straps is their minimal stretching under load. When a strap is subjected to heavy towing or recovery forces, it may stretch slightly.

However, polyester straps exhibit minimal stretching compared to other materials, which helps maintain a more consistent and predictable performance during use.

This minimal stretching also reduces the risk of the strap suddenly snapping back or recoiling when tension is released, enhancing overall safety.

2. Nylon

Nylon is another popular material for winch straps, known for its high breaking strength and elasticity.

Nylon straps can withstand significant towing and recovery forces, making them suitable for heavy-duty applications.

The elastic nature of nylon allows the strap to stretch slightly under load, which can help absorb shock and reduce the risk of damage to the towed vehicle or recovery equipment.

This elasticity provides a smoother, gradual pull, beneficial in specific towing or recovery tasks.

However, one drawback of nylon compared to polyester is its lower resistance to UV damage.

Nylon straps are more susceptible to degradation when exposed to sunlight for extended periods, which can lead to a reduction in strength and overall durability over time.

If you frequently use your winch straps in sunny conditions, you may need to replace nylon straps more often than polyester straps.

3. Kevlar

Kevlar is a high-performance synthetic fiber known for its exceptional strength and lightweight properties.

Kevlar winch straps offer the highest breaking strength-to-weight ratio among the three main materials, making them an excellent choice for demanding towing and recovery applications.

Despite their incredible strength, Kevlar straps remain lightweight, which makes them easier to handle and reduces the overall weight of your recovery gear.

In addition to their strength and lightweight properties, Kevlar straps are also highly resistant to heat, chemicals, and abrasion.

This makes them suitable for use in a wide range of environments and conditions, including exposure to high temperatures, harsh chemicals, or rough surfaces.

Kevlar’s resistance to these factors helps prolong the life of the winch strap and ensures reliable performance in challenging situations.

When selecting a winch strap material, consider your specific towing and recovery needs, as well as the conditions in which you will be using the strap.

Polyester straps offer an excellent balance of strength, UV resistance, and minimal stretching, making them a popular choice for general-purpose use.

Nylon straps provide high breaking strength and elasticity, which can be advantageous in certain situations, but they may require more frequent replacement if used in sunny conditions.

Kevlar straps offer the ultimate in strength, lightweight performance, and resistance to various environmental factors, but they may come at a higher price point compared to polyester or nylon straps.

Choosing the Right Winch Strap Length and Width

When selecting a winch strap for your towing and recovery needs, choosing the appropriate length and width is crucial to ensuring safe and effective operation.

Let’s take a closer look at these two factors:

Length

The length of your winch strap is an important consideration, as it determines the distance over which you can safely tow or recover a vehicle.

When choosing a strap length, you should consider the maximum distance between your winch and the object being towed or recovered.

The strap should be long enough to comfortably reach the anchor points on both vehicles, with some extra length to spare.

Having extra length is essential for several reasons.

First, it allows for greater flexibility in positioning the vehicles during the towing or recovery process. If you encounter an obstacle or need to reposition the vehicles, having additional strap length can make these adjustments easier and safer.

Second, extra length provides a safety margin in case the strap stretches under load or if you need to create a more gradual pulling angle.

When determining the appropriate strap length, also consider the type of terrain you’ll be working on.

If you frequently operate in off-road or uneven conditions, a longer strap may be necessary to accommodate changes in elevation or to navigate around obstacles.

However, keep in mind that excessively long straps can be more difficult to handle and store, so strike a balance between having sufficient length and maintaining practicality.

Width

The width of a winch strap is directly related to its breaking strength and load capacity.

In general, wider straps have higher breaking strengths and can safely handle heavier loads compared to narrower straps made from the same material.

This is because a wider strap distributes the force over a larger surface area, reducing the stress on any single point of the strap.

When choosing a winch strap width, consider the typical weight of the vehicles or objects you will be towing or recovering.

As a general rule, select a strap with a breaking strength that is at least 3-4 times the weight of the heaviest object you plan to tow.

This provides an adequate safety margin and ensures that the strap can handle the forces involved in the towing or recovery process.

Common winch strap widths range from 1 inch to 4 inches or more. For lighter towing and recovery applications, such as passenger vehicles or small trucks, a 2-inch or 3-inch strap may be sufficient.

For heavier applications, such as large trucks, construction equipment, or industrial machinery, a wider 4-inch or even 6-inch strap may be necessary to provide the required breaking strength and load capacity.

It’s important to note that using a strap with a higher breaking strength than necessary does not pose a risk to your vehicle or equipment.

However, using a strap with insufficient breaking strength can be dangerous, as it may fail under the stress of towing or recovery, potentially causing damage or injury.

When selecting the appropriate winch strap length and width for your needs, always refer to the manufacturer’s specifications and recommendations.

They will provide detailed information on the breaking strengths, load capacities, and suitable applications for each strap size.

By choosing the right length and width for your specific towing and recovery needs, you can ensure safe, reliable, and efficient operation while minimizing the risk of damage to your vehicle or equipment.

Proper Use and Maintenance of Winch Straps

To ensure safe and effective use of your winch straps, follow these guidelines:

Safety precautions:

Always prioritize safety when using winch straps. Before each use, inspect the strap thoroughly for any signs of damage, such as cuts, frays, or excessive wear. Pay close attention to the strap’s edges, as this is where damage often begins. If you notice any significant damage, do not use the strap, as it may fail under load, leading to potential accidents or injuries.

When handling winch straps, always wear protective gloves. This not only protects your hands from potential injuries but also helps prevent the strap from coming into contact with oils, chemicals, or other substances that may degrade the material over time.

It is crucial to never exceed the strap’s rated breaking strength or load capacity. These ratings, based on rigorous manufacturer testing, ensure safe operation. Overloading the strap can cause it to fail suddenly, resulting in serious damage or injury. Always choose a strap with a breaking strength and load capacity appropriate for your specific towing or recovery application.

Inspection

Regular inspections are crucial to maintaining the integrity and reliability of your winch straps. Before and after each use, take the time to carefully examine the strap for any signs of wear, fraying, or damage.

Look for cuts, tears, or abrasions along the length of the strap, paying extra attention to the areas near the hooks or attachment points.

If you notice any significant damage, such as deep cuts or extensive fraying, it is best to retire the strap and replace it with a new one.

Using a damaged strap can greatly increase the risk of failure during use, putting you, your vehicle, and others in danger.

In addition to visual inspections, it is also a good idea to keep a log of your winch strap’s use and inspections. This can help you track the strap’s age, the loads it has been subjected to, and any damage or repairs that have been made.

By maintaining a detailed record, you can make informed decisions about when to replace your winch straps based on their condition and usage history.

Cleaning and storage

Proper cleaning and storage of your winch straps can significantly extend their lifespan and maintain their performance.

After each use, take the time to clean your straps, removing any dirt, mud, or debris that may have accumulated during the towing or recovery operation. This can be done using a soft brush and mild soap, followed by a thorough rinse with clean water.

Once the straps are clean, allow them to air dry completely before storing them. Avoid using heat sources, such as a dryer or direct sunlight, to speed up the drying process, as this can weaken the fibers and reduce the strap’s overall strength.

When storing your winch straps, choose a cool, dry location away from direct sunlight. UV radiation can degrade the strap material over time, leading to weakening and potential failure.

Avoid storing your straps in areas with high humidity or exposure to chemicals, as these conditions can also cause damage to the material.

Store your winch straps in a loose coil or on a wide, smooth surface to avoid kinking or bending.

Avoid hanging the straps on hooks or other narrow objects, as this can cause the fibers to become compressed and weakened over time.

FAQ

Can winch straps be used for lifting people?

No, winch straps should never be used for lifting or supporting people. They are designed for pulling and lifting objects only.

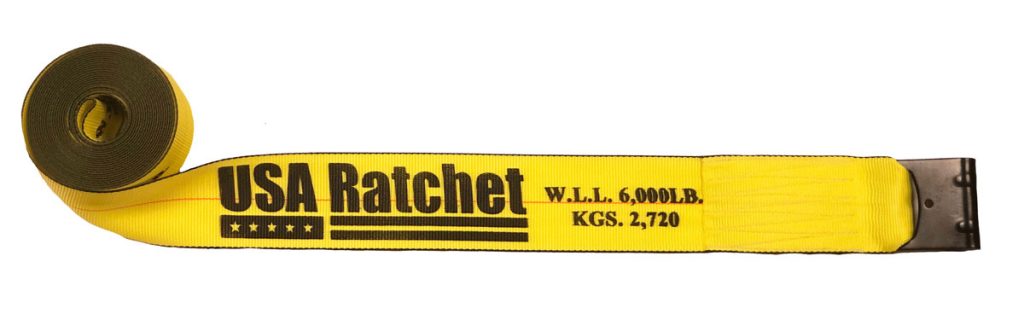

How do I determine the load capacity of a winch strap?

The load capacity of a winch strap is usually specified by the manufacturer and can be found on the strap’s label or in the product documentation. Always use a strap with a load capacity that exceeds the weight of the object being pulled or lifted.

What should I do if a winch strap shows signs of damage?

If a winch strap shows any signs of damage, such as fraying, cuts, or excessive wear, it should be taken out of service immediately and replaced with a new one. Do not attempt to repair damaged winch straps.

Can winch straps be repaired or should they be replaced?

In most cases, winch straps should be replaced rather than repaired. Attempting to repair a damaged strap can compromise its strength and safety, potentially leading to accidents or failures during use.

Conclusion

Winch straps are powerful and versatile tools that play a crucial role in various pulling and lifting applications.

By understanding their purpose, functionality, and proper use, you can ensure safe and efficient operations while maximizing the benefits of these essential tools.

Always prioritize safety, choose high-quality winch straps, and follow manufacturer guidelines and industry best practices.

With the right knowledge and equipment, you’ll be well-prepared to tackle a wide range of pulling and lifting tasks.